Novemba . 23, 2024 04:42 Back to list

wafer butterfly valve

Understanding Wafer Butterfly Valves A Comprehensive Overview

Wafer butterfly valves are essential components in various industrial applications, renowned for their streamlined design and efficiency in controlling fluid flow. With their unique characteristics and functionalities, they form a critical part of many piping systems, particularly where space and weight constraints are a consideration.

What is a Wafer Butterfly Valve?

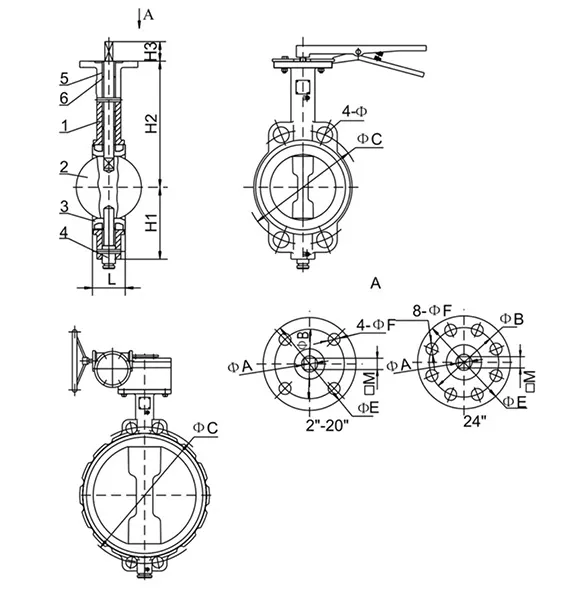

At its core, a wafer butterfly valve consists of a circular disc that rotates around an axis. The disc serves as a control element that can either allow or prevent the flow of fluids through a pipeline. Unlike traditional valves, which often require a substantial amount of space, the wafer butterfly valve is designed to fit between two flanges, making it an ideal choice for systems with limited space.

The term wafer refers to its flat, compact design, which lacks the bulky body structure typical of other types of valves. This design minimizes the valve's footprint while maintaining operational efficiency, thereby making it suitable for various applications, including HVAC systems, water treatment facilities, and more.

Key Features and Advantages

One of the most salient advantages of wafer butterfly valves is their lightweight construction. This feature not only simplifies installation and maintenance but also reduces the overall load on the piping system. Additionally, the compact design allows for easier transport and handling, adding to their practicality in various settings.

Another significant benefit is versatility. Wafer butterfly valves can be constructed from a range of materials, including stainless steel, cast iron, and PVC, enabling their use in different environments and conditions. Whether dealing with corrosive fluids or high-temperature steam, there is likely a suitable wafer butterfly valve to meet the demands of the application.

The design of the valve permits rapid opening and closing, which is crucial in applications where prompt fluid control is necessary. This swift operation also helps to reduce wear and tear, contributing to the longevity of the valve. Furthermore, the simple design of wafer butterfly valves translates into lower maintenance requirements and costs over time.

wafer butterfly valve

Installation and Use

Installation of wafer butterfly valves is straightforward, primarily because they are designed to be sandwiched between two flanges. This allows for a minimal number of connections, which reduces the potential for leaks and points of failure.

When selecting a wafer butterfly valve, it’s crucial to consider factors such as the size of the pipeline, the type of fluid being controlled, and the operating pressure and temperature. These factors will influence the choice of material and the specific type of wafer butterfly valve, whether it's a resilient seated, metal seated, or high-performance variant.

Applications in Industry

Wafer butterfly valves find applications across numerous industries. In the water and wastewater treatment sector, they are often used to regulate flow and pressure. Their durability and resistance to corrosion make them ideal for managing various types of fluids, including sewage and industrial wastewater.

The food and beverage industry also benefits from wafer butterfly valves, where hygiene and cleanliness are paramount. These valves can be manufactured with materials that comply with food safety regulations, ensuring that the quality and safety of consumables are maintained.

In HVAC systems, wafer butterfly valves regulate airflow, which is vital for maintaining temperature and ensuring adequate ventilation in buildings. Their ability to manage large volumes of air efficiently makes them a preferred choice in both commercial and residential HVAC applications.

Conclusion

Wafer butterfly valves are an exemplary choice for many industries requiring effective fluid control in a compact design. Their advantages, including lightweight construction, versatility, and rapid operation, coupled with their straightforward installation process, make them indispensable in modern piping systems. As industries continue to evolve and demand more efficient solutions, wafer butterfly valves will likely remain at the forefront of fluid control technology.

Share

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025