Novemba . 08, 2024 17:45 Back to list

rubber expansion joint price

Understanding the Pricing of Rubber Expansion Joints

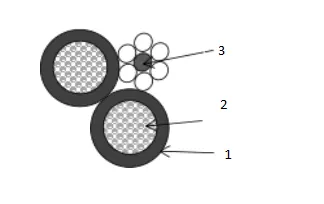

Rubber expansion joints are essential components in various piping and ducting systems. They accommodate movement caused by thermal expansion, vibration, and misalignment. The pricing of rubber expansion joints can be influenced by various factors such as material quality, size, design complexity, and the specific application requirements. This article aims to explore the factors affecting the price of rubber expansion joints and how to make informed purchasing decisions.

1. Material Quality

The material used in manufacturing rubber expansion joints plays a critical role in determining their price. There are several types of rubber compounds available in the market, including natural rubber, neoprene, EPDM (ethylene propylene diene monomer), and silicone. Each type of rubber has its unique properties; for instance, EPDM has excellent resistance to weathering, ozone, and temperature extremes, making it suitable for outdoor applications. Consequently, the cost of rubber expansion joints made from higher-grade or specialized materials is typically higher due to their improved performance and longevity.

2. Size and Dimensions

The size and dimensions of rubber expansion joints significantly impact their price. Larger joints require more material and may need more complex manufacturing processes. Additionally, the application’s pressure ratings and size will dictate the joint’s dimensions, leading to variations in price. Standard sizes are often more economical as they are produced in larger quantities, while custom sizes may incur higher costs due to specialized manufacturing techniques.

3. Design and Complexity

The design of a rubber expansion joint can also affect its price. More complex designs, such as those including multiple layers, special reinforcements, or unique configurations to address specific system requirements, may increase production costs. Simple, standard designs are usually cheaper, while customized solutions that require engineering and development will come with a premium.

rubber expansion joint price

Different applications may necessitate specific features, such as fabric reinforcements or unique flange configurations. For example, joints used in high-pressure systems or corrosive environments often require additional design considerations, leading to an increase in price. Understanding the end-use of the expansion joint is crucial for selecting the right product and justifying its cost.

5. Manufacturer Reputation

The reputation and experience of the manufacturer can also influence pricing. Established manufacturers that provide high-quality products, backed by warranties and certifications, may charge more for their products. It is essential to weigh the price against the value offered, including reliability, customer support, and compliance with industry standards.

6. Quantity and Bulk Discounts

When purchasing rubber expansion joints, especially for large projects, the quantity can significantly affect the overall cost. Many suppliers offer bulk discounts or pricing structures that reduce the per-unit price when purchasing in larger quantities. It is always advisable to inquire about the potential for discounts when ordering multiple units.

7. Shipping and Handling Costs

Finally, don’t forget the additional costs that may arise from shipping and handling. Depending on the supplier’s location and the delivery destination, shipping costs can fluctuate based on weight and dimensions. It’s important to factor these expenses into the total cost of purchasing rubber expansion joints.

Conclusion

In conclusion, the pricing of rubber expansion joints is influenced by various factors, including material quality, size and dimensions, design complexity, application requirements, and the manufacturer’s reputation. Understanding these factors can help you make informed purchasing decisions and select the right expansion joints for your specific needs. When considering a purchase, always balance the initial cost against the long-term benefits, reliability, and performance of the product. By doing so, you’ll ensure that your investment in rubber expansion joints serves your system effectively for years to come. Whether for industrial, commercial, or residential applications, selecting the right expansion joint contributes significantly to the overall efficiency and longevity of your piping systems.

Share

-

Gate Valve Non Rising is IdealNewsApr.27,2025

-

Different sizes of butterfly valveNewsApr.27,2025

-

Choosing the Right Wire Cable Manufacturers MattersNewsApr.27,2025

-

Choosing the Best Butterfly ValveNewsApr.27,2025

-

Best Y Type Strainer Supplier and Y StrainersNewsApr.27,2025

-

A Guide for Industrial ApplicationsNewsApr.27,2025