Desemba . 29, 2024 16:27 Back to list

Enhanced Performance of Lined Butterfly Valves for Reliable Fluid Control Solutions

Understanding Lined Butterfly Valves Key Specifications and Benefits

Lined butterfly valves are critical elements in various industries, particularly in processes involving corrosive, abrasive, or high-temperature fluids. Their design combines the advantages of traditional butterfly valves with the protective capabilities of a lining material, offering enhanced performance and longevity. In this article, we'll delve into the specifications, features, and benefits of lined butterfly valves, highlighting why they are a preferred choice in many applications.

What is a Lined Butterfly Valve?

A lined butterfly valve is a type of quarter-turn valve that utilizes a rotating disc as its primary closure element. Unlike standard butterfly valves, lined versions have a protective lining, often made of materials like rubber or PTFE (polytetrafluoroethylene), which provides resistance to corrosion and abrasion. This lining shields the valve body from the media flowing through it, thereby extending its lifespan and reducing maintenance requirements.

Key Specifications

1. Materials Lined butterfly valves typically feature a body made of stainless steel or carbon steel, coupled with a linings material that offers optimal resistance to chemicals and environmental factors. Common lining materials include EPDM, PTFE, and Neoprene, which are selected based on the type of fluid they will handle.

2. Size Range These valves come in various sizes to accommodate different applications. They can range from small diameters of 2 inches to large sizes of up to 48 inches or more, catering to diverse industry requirements.

3. Pressure Ratings Lined butterfly valves are designed to handle a range of pressure ratings, typically up to 150 PSI or more, depending on the material and design specifications. This flexibility allows them to be used in high-pressure environments while ensuring safety and performance.

4. Temperature Range The lining materials can also withstand a variety of temperatures. PTFE-lined valves, for example, can operate effectively in temperatures ranging from -50°F to 300°F (-45°C to 150°C), making them suitable for various applications, including those involving steam or hot fluids.

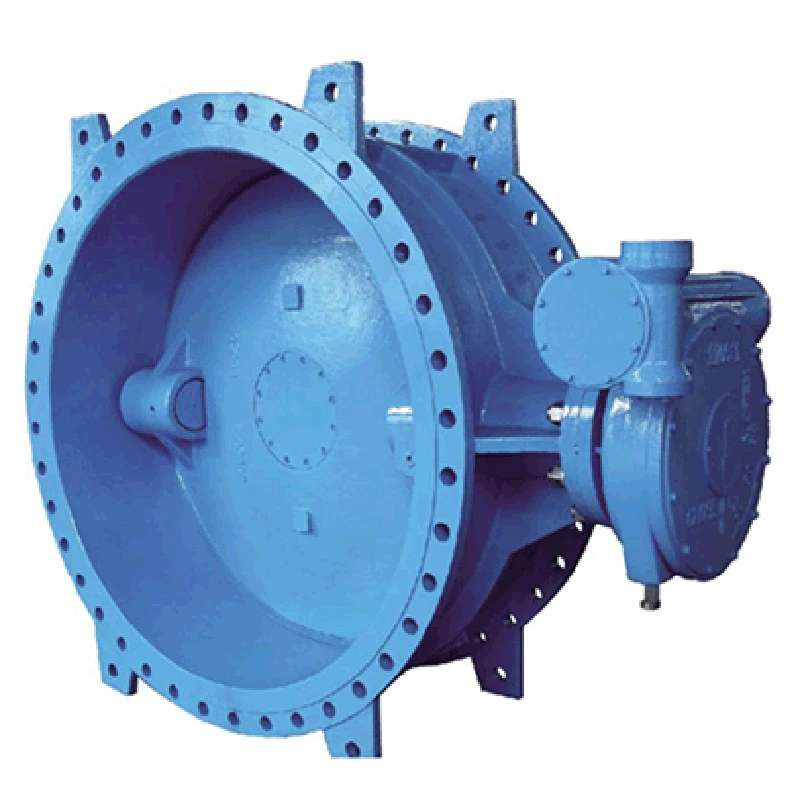

lined butterfly valve

5. Actuation Options Lined butterfly valves can be manually operated or equipped with actuators for automated control. Common actuation methods include electric, pneumatic, and hydraulic actuators, enabling precise control over fluid flow.

Benefits of Lined Butterfly Valves

1. Corrosion Resistance One of the primary advantages of lined butterfly valves is their resistance to corrosion. The lining material protects the valve body, making it ideal for use in chemical processing, wastewater treatment, and other aggressive environments.

2. Lower Maintenance Costs The protective lining not only enhances the valve's durability but also minimizes maintenance needs. With reduced wear and tear, operators can expect longer intervals between repairs and replacements, leading to significant cost savings.

3. Improved Flow Control Lined butterfly valves offer excellent flow characteristics. The disc design provides a smooth flow path, reducing turbulence and pressure loss. This makes them suitable for a variety of applications, including water treatment plants, oil and gas, and power generation.

4. Versatility These valves are versatile and can be used in a wide range of applications due to their ability to handle various fluids, including slurries, corrosive chemicals, and gases. This flexibility broadens their applicability across industries like pharmaceuticals, food processing, and chemical manufacturing.

5. Ease of Installation Lined butterfly valves are relatively easy to install and maintain due to their lightweight design and simple quarter-turn operation. This can reduce the labor required during installation and maintenance, contributing to overall project efficiency.

Conclusion

Lined butterfly valves are essential for industries requiring reliable and resilient flow control solutions. Their unique design and capabilities make them suitable for handling challenging fluids while providing benefits such as corrosion resistance, lower maintenance costs, and improved flow characteristics. As industries continue to advance and evolve, lined butterfly valves will remain a vital component in ensuring operational safety and efficiency. Whether in chemical processing or wastewater management, these valves provide the durability and performance required for successful operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025