Desemba . 05, 2024 14:26 Back to list

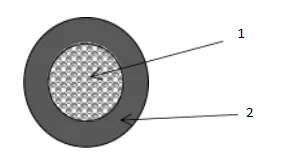

flange dismantling joint

Understanding Flange Dismantling Joints A Comprehensive Overview

Flange dismantling joints are essential components in piping systems, particularly in industrial and commercial settings where maintenance and flexibility are critical. These joints allow for easy disassembly and reassembly of piping without the need for extensive tools or disassembly of surrounding equipment. This article delves into the design, application, and benefits of flange dismantling joints, providing an insightful guide for engineers, technicians, and maintenance personnel.

What is a Flange Dismantling Joint?

A flange dismantling joint is a mechanical fitting designed to connect two sections of pipe. Unlike traditional fixed flanges that require the entire pipe section to be removed for maintenance, dismantling joints enable quick access to the internal piping, valves, or other components. They feature a special design that incorporates adjustable telescopic features, allowing operators to extend or retract the joint during installation or maintenance activities. This adaptability makes them an ideal choice for various piping systems, including those used in water treatment, HVAC, and industrial manufacturing.

Key Features of Flange Dismantling Joints

1. Telescopic Design The hallmark of flange dismantling joints is their telescopic function. This feature grants users the ability to easily adjust the length of the joint, accommodating various pipe sizes and configurations without needing to cut or replace pipes.

2. Ease of Installation These joints simplify the installation process. With standard flanged connections at both ends, installation is straightforward, fitting seamlessly into existing piping systems.

3. Robust Materials Flange dismantling joints are typically constructed from durable materials, such as carbon steel or stainless steel, which provide resistance to corrosion and wear. The choice of material often depends on the specific application and the environment in which the joint will be used.

4. Sealing Mechanism A reliable sealing mechanism is crucial in maintaining the integrity of the piping system. Most dismantling joints are equipped with high-quality gaskets designed to prevent leaks, ensuring that the system operates efficiently.

Applications of Flange Dismantling Joints

Flange dismantling joints find utility in various applications across multiple industries

flange dismantling joint

- Water and Wastewater Treatment These joints are prevalent in water supply and wastewater management systems, where regular maintenance is necessary for efficient operation.

- HVAC Systems In heating, ventilation, and air conditioning systems, dismantling joints facilitate easy access for maintenance and system adjustments, contributing to improved performance.

- Industrial Process Plants Chemical processing and manufacturing plants utilize flange dismantling joints to allow quick access to piping systems for repairs and inspections, minimizing downtime.

- Fire Protection Systems In fire sprinkler systems, these joints allow for efficient modifications and maintenance, ensuring that the system remains operational and compliant with safety standards.

Benefits of Using Flange Dismantling Joints

1. Time-Saving The ability to dismantle and reassemble quickly reduces maintenance time significantly. This efficiency translates to lower labor costs and enhanced productivity.

2. Cost-Effective Maintenance By minimizing the need for extensive rework or complete disassembly of pipeline systems, flange dismantling joints contribute to cost savings over the life of the installation.

3. Flexibility in Design The customizable nature of dismantling joints allows engineers to design more flexible piping layouts that can adapt to future expansions or changes in operational processes.

4. Reduced Downtime With faster maintenance and repair capabilities, these joints lead to reduced downtime, which is critical for industries where every minute of operation counts.

Conclusion

Flange dismantling joints represent a vital innovation in piping technology, delivering significant benefits in terms of maintenance efficiency, cost savings, and flexibility in system design. Their broad applications across various industries underscore their importance in modern engineering solutions. By understanding the features and advantages of these joints, professionals can better implement them into their piping systems, ensuring longevity and reliability in operations. As industries continue to evolve, the capability for quick access and easy maintenance will become increasingly essential, making flange dismantling joints a compelling choice for future projects.

Share

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025