Novemba . 23, 2024 03:07 Back to list

flanged gate valve

Understanding Flanged Gate Valves

Flanged gate valves are essential components widely used in various industries for controlling fluid flow in pipelines. Their design incorporates a distinctive mechanism that allows for a straight-through flow path, making them ideal for applications requiring minimal pressure drop. This article explores the features, advantages, and applications of flanged gate valves, emphasizing their significance in modern engineering systems.

Design and Features

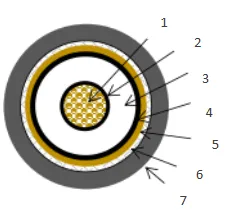

Flanged gate valves consist of two primary parts the valve body and the gate, which can be raised or lowered by manipulating the handwheel or actuator connected to the valve stem. The flanged ends allow for easy connection to piping systems, facilitating straightforward installation and maintenance. Available in various materials such as cast iron, stainless steel, and ductile iron, these valves can withstand different operating conditions, including high pressures and temperatures.

One of the defining features of flanged gate valves is their sealing mechanism. When the valve is fully closed, the gate sits tightly against the seat, creating an effective barrier that prevents fluid leakage. Conversely, when the valve is fully opened, the gate is completely retracted, allowing for an unobstructed flow, which is particularly beneficial in applications requiring high flow rates.

Advantages

1. Bidirectional Flow Flanged gate valves provide bidirectional flow control, meaning they can effectively manage fluids coming from either direction. This characteristic is crucial in systems where flow direction may change.

2. Minimal Pressure Drop Unlike other valve types, such as globe valves, flanged gate valves offer lower resistance to flow when fully opened, resulting in minimal pressure loss. This quality is important in applications where maintaining pressure is critical.

3. Durability and Longevity Constructed from robust materials, these valves are designed to withstand harsh operating conditions. Their longevity reduces the need for frequent replacements, leading to lower maintenance costs over time.

flanged gate valve

4. Simple Operation The straightforward design facilitates ease of operation. Whether operated manually or using an actuator, the process of opening and closing a flanged gate valve is typically efficient and uncomplicated.

Applications

Flanged gate valves are employed in a variety of sectors, including

- Water and Wastewater Treatment These valves are commonly used to regulate water flow in treatment plants, ensuring optimal operation of filtration and distribution systems.

- Oil and Gas Industry In pipelines transporting hydrocarbons, flanged gate valves play a critical role in managing flow rates and ensuring safety during operations.

- Chemical Processing The durability and chemical resistance of flanged gate valves make them suitable for controlling aggressive fluids in chemical plants.

- Power Generation These valves are also utilized in steam and cooling systems within power plants, where they help maintain efficient energy production.

Conclusion

Flanged gate valves are vital components in fluid management systems across various industries. Their simple yet effective design, coupled with the benefits of bidirectional flow, minimal pressure drop, and durability, makes them a preferred choice for engineers and operators alike. As industries continue to evolve and adapt to new challenges, the reliability and efficiency of flanged gate valves will undoubtedly remain essential in the quest for improved operational performance and sustainability. Understanding their applications and advantages allows professionals to make informed decisions that enhance the effectiveness of their fluid control systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025