Novemba . 17, 2024 18:04 Back to list

electronic ball valve

Understanding Electronic Ball Valves Functionality and Applications

In the realm of fluid control systems, electronic ball valves have emerged as a pivotal solution, offering enhanced precision and ease of operation. These sophisticated devices combine mechanical functionality with electronic control, allowing for efficient management of fluid flow in a myriad of applications.

What is an Electronic Ball Valve?

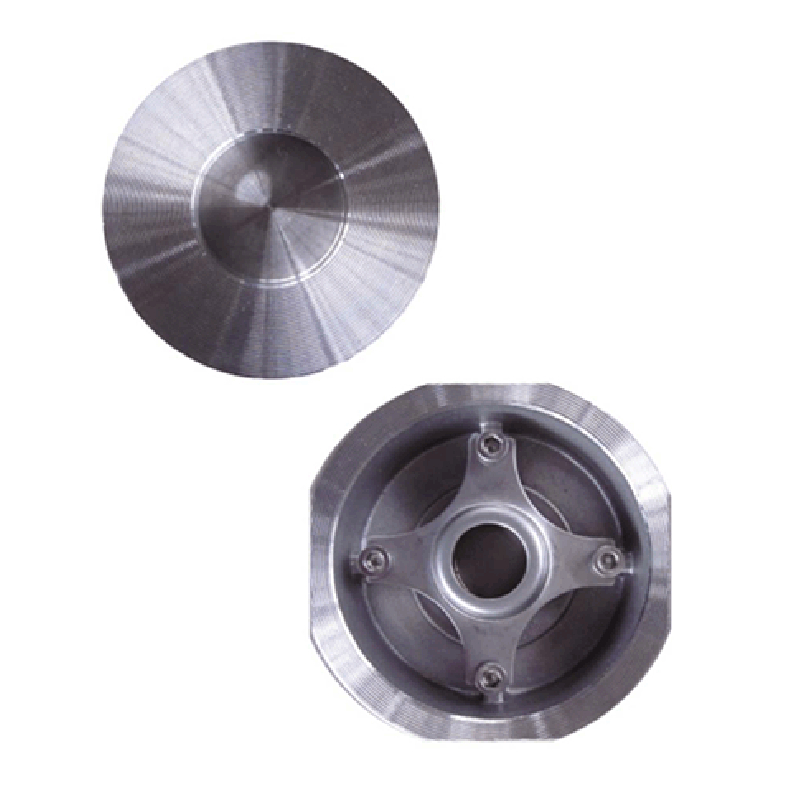

An electronic ball valve is a type of valve that utilizes a spherical closure element (the ball) to regulate fluid flow. The ball has a hole through the center, which aligns with the flow path when in the open position and obstructs it when rotated to the closed position. Unlike traditional manually operated ball valves, electronic ball valves employ an electric actuator—typically a stepper motor or a servo motor—to facilitate automated control.

Components of Electronic Ball Valves

The main components of an electronic ball valve include

1. Ball Mechanism The core component that determines whether the valve is open or closed. 2. Electric Actuator Converts electrical signals into mechanical movement, rotating the ball to the desired position. 3. Sensor Systems Provide feedback about the valve’s position and flow status, enabling precise control. 4. Control Unit Processes input commands and regulates the actuator based on real-time data.

Advantages of Electronic Ball Valves

electronic ball valve

1. Precision Control Electronic ball valves can be finely tuned to control the flow rate, making them ideal for applications where accuracy is paramount. 2. Automation Integration with control systems allows for remote operation and automation, reducing the need for manual intervention and enhancing operational efficiency. 3. Reduced Physical Strain Operators are relieved from the physical demands of manually adjusting valves, contributing to safety and comfort in industrial settings. 4. Consistent Performance The electronic control system ensures reliable and uniform valve operation, leading to improved system stability and reduced risk of failures.

Applications of Electronic Ball Valves

Electronic ball valves have a wide variety of applications across different industries, including

1. Water and Wastewater Treatment Used for precise flow control in treatment plants, electronic ball valves help optimize chemical dosing and maintain environmental compliance. 2. HVAC Systems In heating, ventilation, and air conditioning systems, these valves regulate the flow of heated or cooled fluids, contributing to energy efficiency. 3. Food and Beverage Industry Compliance with hygiene and safety standards makes electronic ball valves a preferred choice for controlling liquid flow in food and beverage processes. 4. Chemical Processing Given their ability to handle corrosive materials safely, they are extensively used in chemical production facilities. 5. Oil and Gas Electronic ball valves are critical in upstream and downstream operations, where they manage the flow of hydrocarbons under various temperature and pressure conditions.

Conclusion

The evolution of electronic ball valves represents a significant advancement in fluid control technology. By integrating electronic components with robust mechanical structures, these valves enhance operational efficiency, precision, and safety across numerous industries. As automation continues to shape modern industrial processes, the adoption of electronic ball valves is likely to expand, paving the way for smarter, more responsive fluid management systems.

In summary, whether in a manufacturing plant, a water treatment facility, or a complex chemical processing unit, electronic ball valves are becoming indispensable tools that contribute to operational excellence and innovation. Their unique combination of automation, precision, and reliability makes them a worthy investment for industries seeking to improve their fluid control systems. As technology progresses, we can expect even greater developments in the design and functionality of electronic ball valves, marking them as a cornerstone of modern engineering solutions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025