Novemba . 12, 2024 22:32 Back to list

dual plate check valve wafer type

Understanding Dual Plate Check Valve Wafer Type

The dual plate check valve, often referred to as the wafer type check valve, is a crucial component in fluid control systems prevalent in various industries, including water treatment, oil and gas, and power generation

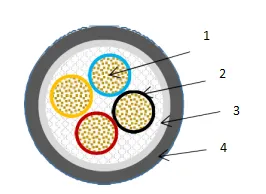

. This type of valve is designed to allow fluid to flow in one direction while preventing backflow, thereby protecting pumps and other equipment from damage.The wafer design means that the valve sits between two flanges in a piping system, providing a compact and lightweight solution compared to traditional check valves. This design is not only space-saving but also simplifies installation and maintenance. The dual plate configuration, which consists of two discs, allows for quick opening and closing, thus reducing the risk of water hammer—a pressure surge that can occur when the flow of fluid is suddenly stopped.

A key feature of dual plate check valves is their ability to operate efficiently at varying flow rates. The dual plates are spring-loaded, which helps them remain closed when there is no flow or when the flow direction reverses. This mechanism minimizes the risk of backflow, which can lead to system inefficiency and costly repairs. Additionally, the quick response time of the plates ensures that the valve functions effectively, enhancing the overall reliability of the fluid system.

dual plate check valve wafer type

Materials commonly used in the construction of wafer type check valves include stainless steel, ductile iron, and other corrosion-resistant alloys. This choice of materials ensures durability and longevity, making them suitable for both high-pressure and corrosive environments. The option for different materials also allows for customization based on the specific requirements of the application.

Another advantage of the dual plate check valve wafer type is its low-pressure drop characteristics. This makes it an energy-efficient choice, as it minimizes the energy losses that can occur during fluid transportation. Furthermore, the compact design reduces the overall weight of the piping system, leading to lower installation costs and easier handling.

In conclusion, the dual plate check valve wafer type is an essential component in modern hydraulic systems, combining efficiency, reliability, and ease of installation. As industries strive for improved operational performance, the adoption of such innovative solutions continues to grow, paving the way for enhanced fluid management and system integrity.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025