Desemba . 19, 2024 01:25 Back to list

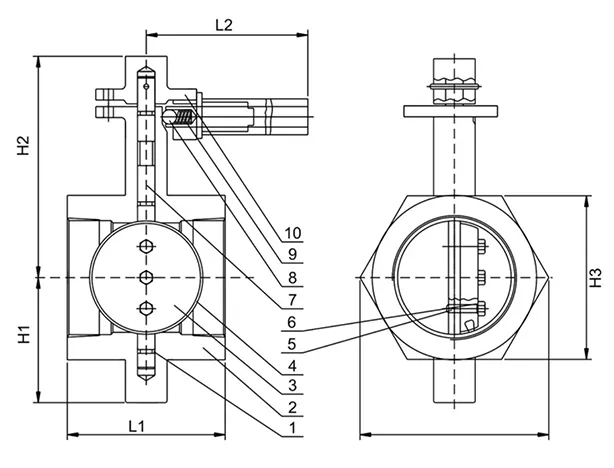

di air valve

Understanding DI Air Valves Essential Components for Efficient Water Management

In the realm of water management, particularly in irrigation systems and drainage, the use of air valves is crucial for maintaining efficiency and preventing operational issues. Among the various types of air valves available, the DI air valve—made from ductile iron—has gained considerable attention due to its robust design and effective functionality. This article explores the purpose, benefits, and applications of DI air valves, emphasizing their integral role in modern water distribution systems.

What is a DI Air Valve?

A DI air valve is a specialized mechanism designed to release or admit air into a pipeline system. It primarily serves two vital functions

1. Air Release During the operation of a pipeline, air can accumulate, leading to air pockets that hinder water flow and reduce efficiency. A DI air valve allows trapped air to escape, thereby maintaining optimal performance.

2. Air Intake When a pipeline is draining, such as when water is removed from a section of the system for maintenance, the DI air valve allows external air to enter. This prevents vacuum conditions that could collapse the pipe or cause other damage.

Benefits of DI Air Valves

1. Durability Made from ductile iron, DI air valves offer superior strength compared to those made from plastic or other materials. This durability ensures they can withstand high pressures and harsh environmental conditions, making them ideal for a variety of applications.

2. Corrosion Resistance While ductile iron is susceptible to corrosion, many DI air valves are coated with protective materials or treated to enhance their resistance. This feature prolongs the lifespan of the valve and minimizes maintenance needs, particularly in corrosive environments.

3. Efficiency By allowing for the timely release and intake of air, DI air valves enhance the efficiency of water transportation systems. They minimize disruptions caused by air pockets, ensuring a steady flow of water and reducing energy consumption.

di air valve

4. Versatility DI air valves can be used in a wide range of applications, from municipal water distribution systems to agricultural irrigation. Their robust construction enables them to be employed in various settings, including high-demand industrial operations.

5. Reduced Maintenance Costs The robust design and materials used in DI air valves mean they generally require less maintenance than their counterparts. This translates into lower operational costs for water management systems over time.

Applications of DI Air Valves

DI air valves find application in several key areas

1. Water Supply Systems In municipal water supply systems, DI air valves are crucial for maintaining consistent water pressure and flow. They help avoid issues related to air entrapment, which can lead to inefficient operation and water hammer effects.

2. Irrigation Systems Agricultural irrigation relies heavily on DI air valves to release air from pipelines and prevent the formation of air pockets that can disrupt water distribution. Their durability makes them suitable for the demanding conditions often encountered in farming.

3. Sewage and Wastewater Management In sewage and wastewater systems, DI air valves play an essential role in maintaining flow stability and preventing pressure buildup. This facilitates smoother operation and reduces the risk of system failures.

4. Fire Protection Systems In fire protection systems, these valves ensure that water supply lines remain free from air locks, providing a reliable source of water when needed most.

Conclusion

DI air valves are indispensable components in the efficient management of water distribution systems. Their ability to alleviate air-related issues enhances the performance and longevity of pipelines, making them a worthwhile investment for municipalities and industries alike. As water management continues to evolve, the importance of reliable components like DI air valves will only increase, ensuring that we can meet the growing demands for clean, accessible water while maintaining infrastructure integrity. Understanding and implementing these valves in various systems can lead to significant improvements in operational efficiency and cost-effectiveness, thereby supporting sustainable water management practices for the future.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025