Desemba . 21, 2024 03:32 Back to list

butterfly check valve

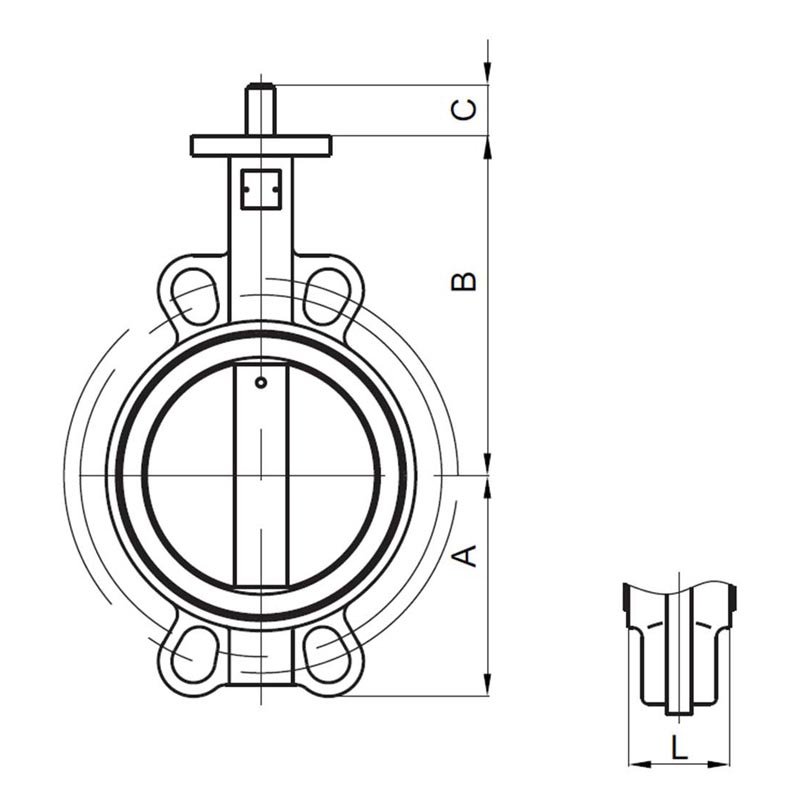

Understanding Butterfly Check Valves Functionality and Applications

Butterfly check valves are essential components in various fluid handling systems, designed to prevent backflow while allowing the flow of fluids in one direction. Recognized for their simple design and efficient operation, butterfly check valves are favored in many industrial and municipal applications. In this article, we delve into the functionality, benefits, and applications of butterfly check valves.

Functionality of Butterfly Check Valves

The critical component of a butterfly check valve is its disc, which is mounted on a shaft in the center of the valve body. When fluid flows in the designated direction, the disc swings open, allowing the fluid to pass through. In the event of a pressure drop or reverse flow, the disc automatically closes due to the weight of the disc as well as the fluid pressure acting against it, effectively preventing backflow.

Butterfly check valves typically come in two configurations spring-loaded and non-spring-loaded. The spring-loaded variety utilizes a spring mechanism to keep the valve closed until enough pressure from the flow causes it to open. The non-spring-loaded version relies solely on the fluid pressure and gravity to operate. The choice between the two types depends on the specific application and requirements of the system.

Advantages of Butterfly Check Valves

One of the most significant advantages of butterfly check valves is their low pressure drop. Compared to other types of check valves, such as swing or globe check valves, butterfly check valves have a compact design and a smaller profile, which minimizes turbulence and friction loss when fluid flows. This characteristic makes them ideal for applications where maintaining efficient flow rates is critical.

Another advantage is their lightweight design. Made primarily from materials like stainless steel, ductile iron, or PVC, butterfly check valves can be easily installed and maintained without the need for heavy machinery. Their simple construction also contributes to lower manufacturing costs, making them an economical choice for both manufacturers and end-users.

butterfly check valve

Butterfly check valves are also versatile and can be employed in a variety of applications, including water and wastewater treatment, chemical processing, food and beverage production, and HVAC systems. Their ability to withstand various pressure and temperature conditions makes them suitable for various industrial processes.

Applications of Butterfly Check Valves

The applications of butterfly check valves are vast and diverse. In the water and wastewater industry, these valves are commonly used to manage flow in piping systems, ensuring that water moves efficiently toward treatment facilities while preventing backflow that could lead to contamination.

In the chemical processing industry, butterfly check valves are crucial for controlling the flow of corrosive liquids and gases. Their resilience and compatibility with various chemicals ensure that the integrity of the piping system is maintained while minimizing the risk of leaks and backflow.

Food and beverage processing also benefits from butterfly check valves, which are essential in maintaining sanitary conditions. These valves are designed to meet strict hygiene regulations, ensuring that there is no contamination in the production process. Their quick operation and reliability help maintain consistent flow rates, essential for efficient production.

HVAC systems utilize butterfly check valves to manage the flow of air and refrigerants efficiently. By preventing backflow, these valves help maintain optimal pressure within the system, contributing to energy efficiency and system longevity.

Conclusion

Butterfly check valves are indispensable in various sectors due to their unique design and operational efficiency. By preventing backflow, they play a crucial role in various industries, including water treatment, chemical processing, food and beverage, and HVAC systems. With benefits such as low pressure drop, lightweight construction, and versatility, butterfly check valves are an economical solution that meets the fluid handling needs of modern applications. As industries continue to evolve, the demand for reliable and efficient components like butterfly check valves will undoubtedly grow, solidifying their place in the future of fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025