Desemba . 12, 2024 21:24 Back to list

1400mm butterfly valve

The 1400mm Butterfly Valve An Essential Component in Modern Industry

Butterfly valves are a crucial component in various industrial applications, known for their simple design, lightweight construction, and efficient operation. Among these, the 1400mm butterfly valve stands out due to its significant size and capability to handle substantial flow rates. This article explores the features, functionalities, applications, and benefits of the 1400mm butterfly valve, highlighting why it is an indispensable part of modern fluid control systems.

Understanding Butterfly Valves

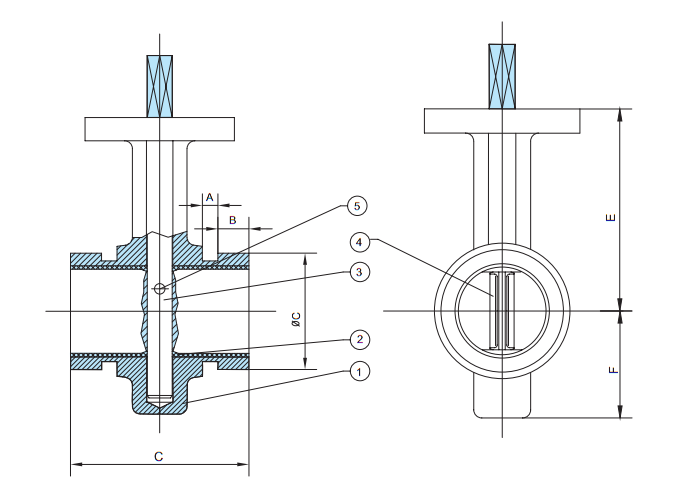

A butterfly valve is a quarter-turn valve that uses a rotating disc to control the flow of fluid through a pipe. When the valve handle or actuator is turned, the disc rotates to open or close the passage. This design allows for quick and efficient adjustments to flow rates, making butterfly valves ideal for various applications. They are often made from materials such as cast iron, stainless steel, or plastic, and can be fitted with different sealing materials to suit specific requirements.

Features of the 1400mm Butterfly Valve

1. Size and Capacity The 1400mm diameter makes this type of butterfly valve suitable for large pipelines, capable of handling high volumes of fluids, including water, gas, and chemicals. Its large size allows for a more significant flow area, minimizing pressure loss while still maintaining regulatory compliance.

2. Lightweight Construction Compared to other valve types, the butterfly valve is typically lighter and takes up less space. This is particularly advantageous in larger systems where weight and space constraints are critical.

3. Quick Operation The quarter-turn design allows for rapid opening and closing, which is essential in applications that demand immediate responses to changes in flow conditions. The 1400mm valve can be actuated manually or with pneumatic, electric, or hydraulic actuators for automation.

4. Flow Regulation Butterfly valves can be adjusted to various positions, enabling precise control over flow rates. This flexibility is invaluable in industries where flow conditions fluctuate, requiring constant adjustment.

5. Durability and Maintenance Made from robust materials, 1400mm butterfly valves are engineered to withstand harsh environments, making them suitable for numerous applications. They typically require less maintenance than other valve types, contributing to lower long-term operational costs.

Applications of the 1400mm Butterfly Valve

The versatile 1400mm butterfly valve is used in a wide range of applications across different industries

1. Water Treatment In water distribution systems, butterfly valves help regulate flow and isolate sections of the pipeline for maintenance. Their ability to perform in high-flow environments makes them ideal for pumping stations and treatment facilities.

1400mm butterfly valve

2. Chemical Processing The chemical industry relies heavily on butterfly valves for their capability to handle corrosive substances. The 1400mm valve can be customized with various linings to resist chemical attack, ensuring safe operations.

3. Power Generation Power plants use butterfly valves to control the flow of cooling water and steam within their systems. Their quick operation helps maintain optimal performance and safety standards.

4. HVAC Systems In large heating, ventilation, and air conditioning systems, butterfly valves regulate airflow efficiently, contributing to energy savings and operational efficiency.

5. Mining and Mineral Processing The heavy-duty design of the 1400mm butterfly valve makes it suitable for handling slurries and other abrasive materials found in mining operations.

Benefits of Using the 1400mm Butterfly Valve

The adoption of 1400mm butterfly valves in industrial applications offers several key advantages

1. Cost-Effectiveness With their straightforward design and reduced maintenance needs, butterfly valves present a long-term cost-saving solution for fluid control.

2. Efficiency The ability to quickly adjust flow rates enhances system performance, leading to improved efficiency and productivity in various operations.

3. Space Saving Their compact design allows for more streamlined piping layouts, saving valuable space in industrial facilities.

4. Versatility The adaptability of butterfly valves across different applications and industries underscores their importance in modern engineering practices.

Conclusion

The 1400mm butterfly valve represents a vital innovation in fluid control technology. Its unique combination of large capacity, lightweight construction, quick operation, and low maintenance needs make it an essential component across a multitude of industries. As industries continue to evolve, the demand for efficient and reliable flow control solutions like the 1400mm butterfly valve will undoubtedly remain at the forefront of engineering advancements.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025