Jan . 15, 2025 02:17 Back to list

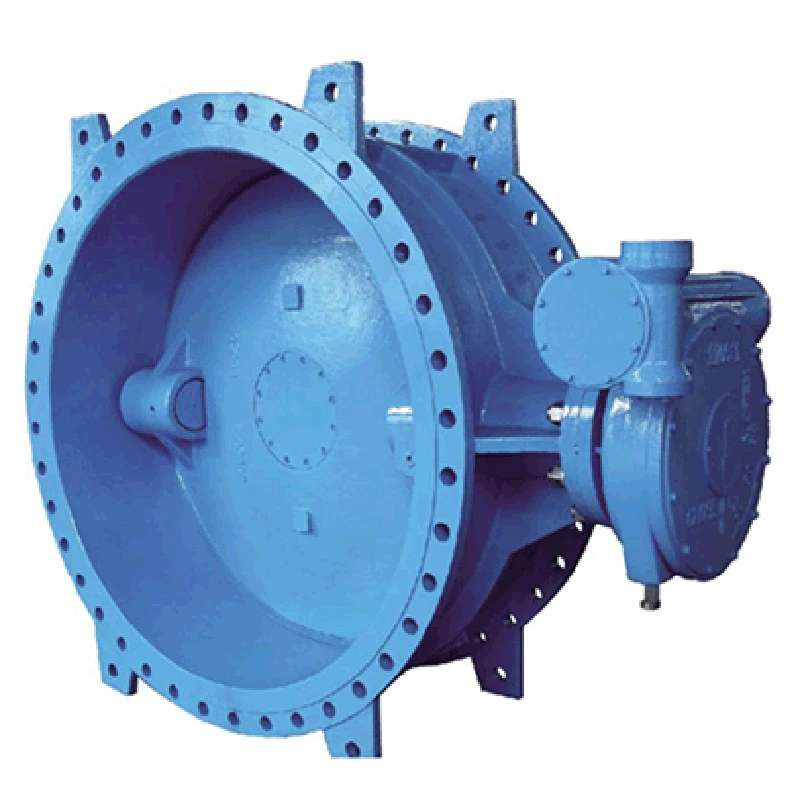

ball type check valve

The SS Ball Valve Flange Type represents a quintessential element in industrial fluid control systems. Made from stainless steel, these valves are engineered for high performance, robustness, and longevity, catering to various industries such as chemical, pharmaceutical, food processing, and more. Typically, these valves play a crucial role in controlling the flow of liquid and gas, ensuring precision and safety in operations.

When discussing authoritativeness, several industry standards govern the design and manufacturing of SS ball valves. Compliance with ISO, ASME, and API standards is vital, as it guarantees a level of quality and reliability that industry professionals can trust. Using certified valves ensures process accuracy and aligns with strict regulatory requirements. Trust in SS ball valves also arises from the established relationships manufacturers have built with their clients over years of reliable service. Case studies from various sectors show consistent positive feedback on their performance, reinforcing their reputation. Experience builds trust, and these valves have a long history of proving themselves effective and reliable. In the ever-evolving landscape of fluid control systems, integrating technological advancements such as automation and remote control capabilities is becoming increasingly common. The latest SS ball valve designs incorporate features that enable seamless integration with digital monitoring systems, offering real-time data to optimize process efficiency further. For those considering investing in SS ball valve flange types, understanding these facets provides confidence. Knowledge about the material science, design intricacies, and industry applications reveals the profound impact these valves can have on operational efficiency and safety. Finally, a solid selection of trusted manufacturers and suppliers ensures that businesses receive not only a product but a partner in achieving operational excellence.

When discussing authoritativeness, several industry standards govern the design and manufacturing of SS ball valves. Compliance with ISO, ASME, and API standards is vital, as it guarantees a level of quality and reliability that industry professionals can trust. Using certified valves ensures process accuracy and aligns with strict regulatory requirements. Trust in SS ball valves also arises from the established relationships manufacturers have built with their clients over years of reliable service. Case studies from various sectors show consistent positive feedback on their performance, reinforcing their reputation. Experience builds trust, and these valves have a long history of proving themselves effective and reliable. In the ever-evolving landscape of fluid control systems, integrating technological advancements such as automation and remote control capabilities is becoming increasingly common. The latest SS ball valve designs incorporate features that enable seamless integration with digital monitoring systems, offering real-time data to optimize process efficiency further. For those considering investing in SS ball valve flange types, understanding these facets provides confidence. Knowledge about the material science, design intricacies, and industry applications reveals the profound impact these valves can have on operational efficiency and safety. Finally, a solid selection of trusted manufacturers and suppliers ensures that businesses receive not only a product but a partner in achieving operational excellence.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025