Nov . 24, 2024 17:29 Back to list

Optimizing Performance in High-Efficiency Butterfly Valves for Industrial Applications

High-Performance Butterfly Valves An Overview

Butterfly valves are essential components in numerous industrial applications, primarily used for regulating flow in pipelines. Among the wide array of butterfly valves available, high-performance butterfly valves stand out due to their exceptional design, material properties, and application versatility. In this article, we will delve into what constitutes a high-performance butterfly valve, its advantages, applications, and the factors to consider when selecting one for specific requirements.

What is a High-Performance Butterfly Valve?

A high-performance butterfly valve is designed to provide superior control and efficiency in flow regulation. Unlike standard butterfly valves, high-performance variants are engineered to handle higher pressures and temperatures, making them suitable for demanding environments. Their enhanced features typically include improved sealing mechanisms, precision-crafted bodies, and more robust materials. Additionally, these valves often have a streamlined design that minimizes turbulence, reducing energy loss and improving flow characteristics.

Features and Benefits

1. Robust Construction High-performance butterfly valves are often made from high-grade materials such as stainless steel, carbon steel, and specialized alloys. This construction enhances their strength, resistance to corrosion, and overall durability, making them ideal for challenging environments like chemical processing plants or wastewater treatment facilities.

2. Improved Sealing Many high-performance butterfly valves incorporate advanced sealing technologies, such as resilient elastomeric seals or metal-to-metal seating. This results in better leakage control, ensuring more efficient operation while maintaining regulatory compliance.

3. Flow Efficiency The design of high-performance butterfly valves minimizes pressure drops, allowing for smoother fluid flow. This characteristic not only saves energy but also contributes to overall system efficiency. The valve’s ability to provide tight shutoff capabilities further ensures that operations are conducted without wastage.

4. Versatile Applications High-performance butterfly valves can be found in various sectors, including oil and gas, water treatment, HVAC systems, and food and beverage production. Their versatility stems from their ability to manage different types of fluids—ranging from gases to viscous liquids—under various operational conditions.

5. Ease of Maintenance The design of high-performance butterfly valves often facilitates easier maintenance and replacement of internal components. This contributes to reduced downtime and lower operational costs, as maintenance personnel can quickly address any issues that may arise.

Applications

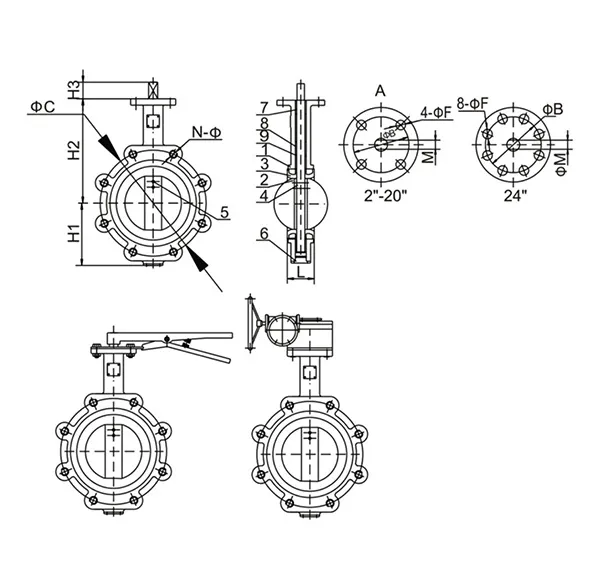

high performance butterfly valve

High-performance butterfly valves are vital in numerous industries, including

- Oil and Gas Used for flow regulation in pipelines, processing facilities, and refineries, these valves handle high-pressure environments and corrosive substances. - Water Treatment In municipal water systems, these valves control the flow of water and wastewater, ensuring efficient treatment processes. - Chemical Processing Designed to manage aggressive chemicals and high temperatures, they play a crucial role in the safe and efficient operation of processing plants. - HVAC Systems High-performance butterfly valves are employed in heating, ventilation, and air conditioning systems to regulate airflow and enhance energy efficiency.

Selecting the Right High-Performance Butterfly Valve

When choosing a high-performance butterfly valve for a specific application, several factors need to be considered

1. Operating Conditions Analyze the temperature and pressure conditions the valve will be exposed to, as well as the type of fluid being handled. This information is critical for selecting the appropriate materials and designs.

2. Flow Requirements Understand the required flow rate and how the valve will fit into the overall system. Evaluate whether a traditional or a high-performance valve is necessary based on the flow characteristics.

3. Control Method Determine how the valve will be operated—manually, pneumatically, or electrically. The control method may impact the selection of valve size, design, and actuator requirements.

4. Regulatory Compliance Ensure that the valve meets any industry standards or regulations that apply to your specific application, especially in sectors like food and beverage or pharmaceuticals.

5. Cost vs. Benefit While high-performance butterfly valves might have a higher upfront cost, their efficiency and longevity may result in significant long-term savings. Conduct a cost-benefit analysis to determine if the initial investment is justified based on projected performance advantages.

Conclusion

High-performance butterfly valves play a crucial role in contemporary industrial applications, offering enhanced flow control, durability, and efficiency. Their robust design and versatility make them suitable for handling a variety of fluids across different sectors. When selecting a high-performance butterfly valve, it is essential to consider the specific operational conditions and requirements to ensure optimal performance and reliability. As industries continue to demand higher efficiency and lower operational costs, the relevance of high-performance butterfly valves is likely to increase, reshaping the landscape of fluid management solutions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025