Dec . 04, 2024 15:15 Back to list

full lug butterfly valve

Full Lug Butterfly Valve An Essential Component in Fluid Control

In industrial and commercial applications, proper fluid regulation is paramount for efficiency and safety. One crucial component employed for this purpose is the butterfly valve, particularly the full lug butterfly valve. This type of valve offers unique design features and functionalities that make it an essential choice in various piping systems.

Definition and Design

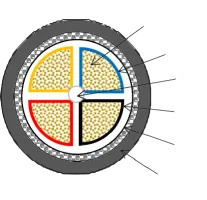

A butterfly valve is a quarter-turn rotational valve that can be used to regulate fluid flow. The full lug designation refers to the valve's design, which includes lugs on both sides of the body that allow for bolting to the pipe flanges. This design provides several advantages, making full lug butterfly valves a popular choice in many industries. Unlike wafer-style butterfly valves, which fit between two flanges, full lug valves can be installed between flanges without needing additional support on the downstream side. This feature is particularly useful in systems where maintenance and replacement of valves without removing adjacent pipeline components is critical.

Benefits of Full Lug Butterfly Valves

1. Versatility Full lug butterfly valves can be used in a wide range of applications, from water treatment plants and chemical processing to HVAC systems and food processing. Their ability to handle various media types, including liquids and gases, further extends their usability.

2. Ease of Installation The lugged design simplifies the installation process. The valve can be easily bolted onto the piping system, ensuring a secure and snug fit. This design means that the valve can be removed for maintenance without disturbing the rest of the piping system.

3. Space Efficiency Full lug butterfly valves are typically compact, making them suitable for installations where space is limited. They provide effective flow control without occupying excessive space, which is advantageous in many industrial settings.

full lug butterfly valve

4. Cost-Effectiveness Due to their simple design and fewer moving parts compared to other valve types, full lug butterfly valves are often more cost-effective in terms of both initial purchase price and maintenance costs over their lifecycle.

5. Reliability These valves exhibit high reliability and durability in harsh working conditions. Made from materials such as stainless steel, ductile iron, or PVC, they can withstand extreme temperatures and pressures, ensuring long-term performance and reduced downtime.

Applications

In industrial settings, full lug butterfly valves are commonly found in wastewater management systems, where they control the flow of various fluids. They are also used in HVAC systems for regulating air flow, in fire protection systems for controlling water supply, and in food and beverage industries for maintaining hygiene while regulating processes.

Moreover, full lug butterfly valves are often deployed in pipelines where quick shut-off capabilities are required. Their quarter-turn operation allows for rapid response to changing conditions, enhancing the safety and efficiency of the entire system.

Conclusion

In summary, the full lug butterfly valve is a crucial component in fluid control systems across various industries. Its unique design offers advantages in terms of installation, versatility, and reliability. As industries continue to demand efficient and effective fluid regulation solutions, the full lug butterfly valve will remain a staple choice, ensuring optimal performance and safety in fluid handling and control. Whether for industrial applications or commercial use, investing in high-quality full lug butterfly valves is essential for maintaining efficient operations and achieving long-term reliability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025