Dec . 23, 2024 14:35 Back to list

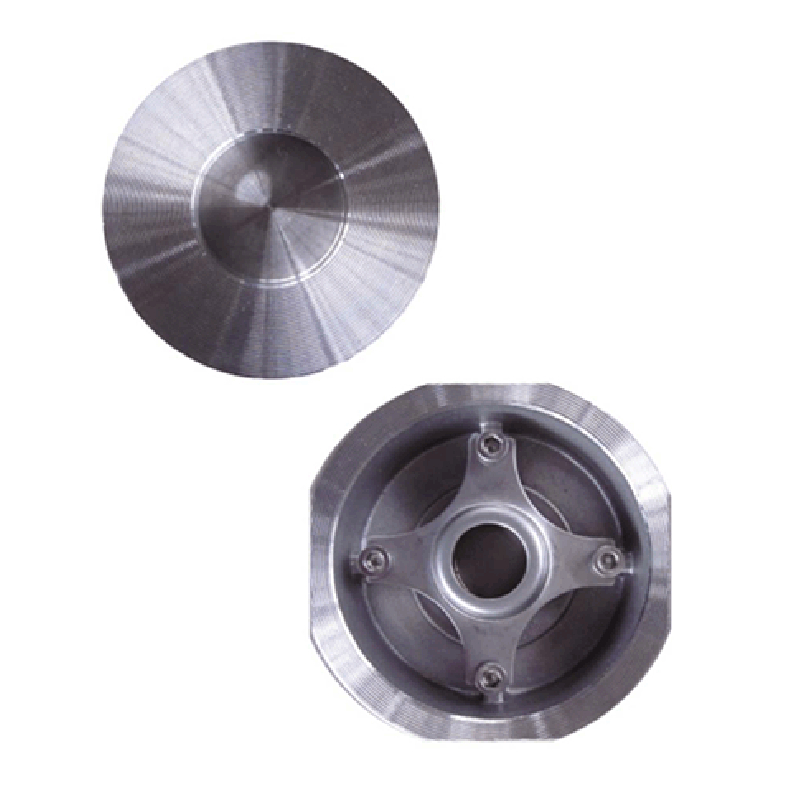

flap check valve

Understanding Flap Check Valves Importance and Functionality

Flap check valves play a crucial role in various fluid systems, ensuring the effective flow of liquids and gases while preventing backflow. These valves, often referred to as swing check valves, are engineered to operate automatically, relying on the flow of the fluid to open and close. Understanding the importance and functionality of flap check valves is essential for those involved in the design, installation, and maintenance of fluid systems.

Definition and Design

A flap check valve consists of a disc or flap that pivots on a hinge within a valve body. When the fluid flows in the intended direction, the pressure lifts the flap, allowing the flow to pass through. However, when the flow attempts to reverse, the flap closes under the influence of gravity and back pressure, effectively sealing the system and preventing any reverse flow. This mechanism is simple yet highly effective, making flap check valves a popular choice across numerous applications.

Applications

Flap check valves are widely used in various industries, including water treatment, sewage systems, chemical processing, and oil and gas operations. Their primary purpose in these systems is to maintain unidirectional flow, safeguarding equipment and infrastructure from potential damage caused by backflow.

1. Water and Wastewater Management In municipal water systems, flap check valves are critical for maintaining the integrity of pipelines and pumps. They prevent backflow that could lead to contamination of potable water sources or overloading of wastewater systems during storm events.

2. Industrial Applications In chemical processing, these valves help protect reactors and other sensitive equipment from backpressure that can cause leaks or operational failures. Their reliability is crucial for maintaining safety and preventing costly downtime.

3. Oil and Gas In oil refining and transportation, flap check valves prevent backflow in pipelines, helping to maintain pressure within the system and ensuring the efficiency of transport processes. Their robust design can withstand the harsh conditions often found in these environments.

Advantages

Flap check valves offer several advantages that make them a preferred option in many applications

- Low Hydraulic Resistance The design of flap check valves allows for minimal resistance to flow when open, promoting efficient system operation. This characteristic is especially beneficial in systems where flow rates are critical.

flap check valve

- Automatic Operation The self-acting nature of flap check valves eliminates the need for external power or manual intervention, making them an ideal choice for locations where access is limited or automation is preferred.

- Durability and Longevity Many flap check valves are constructed from high-quality materials resistant to corrosion and wear, ensuring a long operational life even under challenging conditions.

- Compact Design Flap check valves are generally smaller and lighter than other types of check valves, making installation simpler and reducing the overall footprint of fluid systems.

Considerations for Selection and Maintenance

When selecting a flap check valve for a specific application, several factors need to be considered

- Size and Diameter Valve size should align with the pipe size and the expected flow rates to ensure optimal performance.

- Material The material of construction needs to be compatible with the fluid being handled to prevent corrosion and ensure reliability.

- Installation Orientation While flap check valves can be installed in various orientations, vertical installations often yield the best performance due to gravity assisting in the closure of the flap.

Regular maintenance is essential to ensure the proper functioning of flap check valves. While their design minimizes the need for frequent checks, periodic inspections can help identify wear or buildup that may impede operation.

Conclusion

Flap check valves are an integral component in many fluid systems, providing reliable backflow prevention and ensuring the continuous movement of liquids and gases. Their simple design, combined with their effectiveness in a variety of applications, highlights their significance in industrial, municipal, and commercial settings. Understanding their functionality and maintenance requirements is essential for engineers and professionals who aim to create efficient and safe fluid transport systems. As industries continue to innovate, the reliance on robust and reliable components like flap check valves will remain paramount in achieving operational excellence.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025