Dec . 06, 2024 12:50 Back to list

Flanged Butterfly Valve Options for Efficient Flow Control in Industrial Applications

Flanged Butterfly Valve An Essential Component in Fluid Control Systems

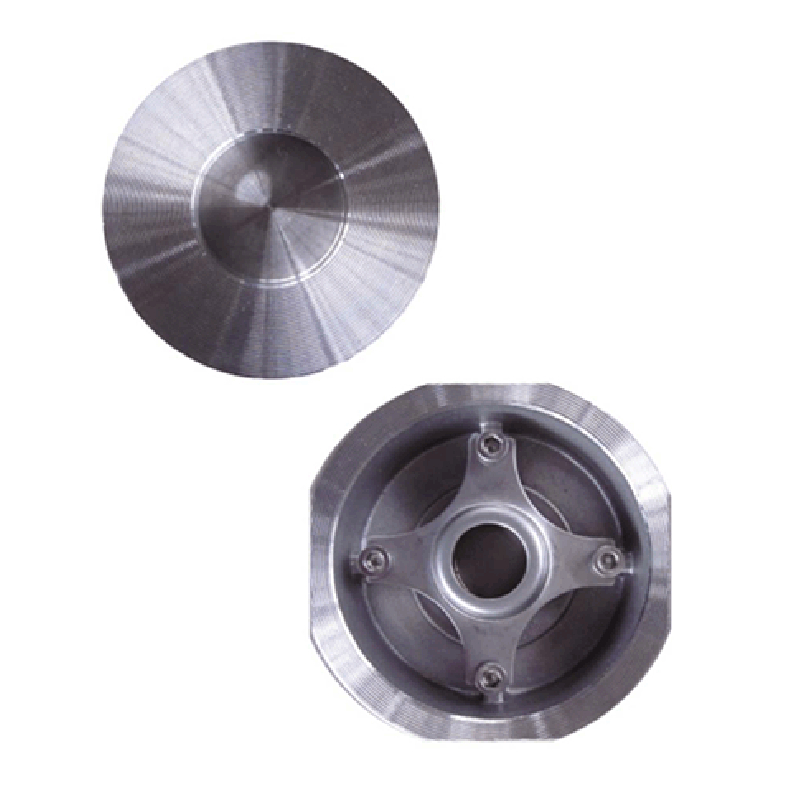

Flanged butterfly valves play a crucial role in various industrial applications, primarily in the management of fluid flow. Unlike traditional valves, the flanged butterfly valve utilizes a simple rotating disc to control the flow of fluid through it. Its design and functionality make it an essential component in numerous engineering processes.

The butterfly valve gets its name from the disc, which resembles a butterfly's wings as it opens and closes. The flanged design means that the valve has flanges—raised edges that allow for easy attachment to piping systems. This feature not only simplifies installation but also ensures a secure connection that minimizes the risk of leaks. The flanged butterfly valve is designed for a variety of applications, including water treatment, chemical processing, and HVAC systems. Its versatility is due to the ability to handle a wide range of pressures and temperatures, making it suitable for different environments.

One of the primary advantages of using flanged butterfly valves is their lightweight construction. Compared to other valve types, they are typically less heavy, which eases the burden on piping systems and reduces the overall installation costs. Moreover, the compact design of these valves allows for space-saving configurations, which is particularly beneficial in constrained environments or systems that require multiple installations.

The operational efficiency of flanged butterfly valves is another noteworthy feature. They can be operated manually or automated using actuators, which enables precise control over the flow of fluids. The quick-acting design of the valve allows it to fully open or close within a 90-degree turn, making it ideal for situations where rapid flow adjustments are necessary. This quick response time ensures optimal control in dynamic fluid systems, helping to maintain desired flow rates and pressure levels.

flanged butterfly valve

In terms of maintenance, flanged butterfly valves are generally easier to service than other valve types. The design is straightforward, which allows maintenance personnel to quickly identify and address issues. Additionally, the use of robust materials in construction helps ensure longevity and reliability, thus reducing the need for frequent replacements.

Depending on the specific application, flanged butterfly valves can be constructed from various materials, including ductile iron, stainless steel, and plastic. This adaptability allows engineers to choose the most appropriate materials based on the type of fluid being controlled, ensuring compatibility and longevity of the valve under operational conditions. Furthermore, many modern flanged butterfly valves come equipped with features such as resilient seating and enhanced sealing technologies, which improve their performance and reduce the risk of leakage.

However, it is important to consider the limitations of flanged butterfly valves. They are best suited for on-off applications or for regulating flow, but may not be the ideal choice for throttling applications that require precise flow control over a range. Understanding these limitations allows engineers and operators to make informed decisions about when and where to utilize flanged butterfly valves effectively.

In conclusion, flanged butterfly valves are an integral part of fluid control systems across various industries. Their lightweight design, ease of installation, operational efficiency, and lower maintenance needs make them a popular choice among engineers and operators alike. As industries continue to evolve and seek more efficient solutions, the importance of reliable components like flanged butterfly valves will only continue to grow. Proper selection and application of these valves can lead to enhanced performance and longevity in any fluid management system, highlighting their vital role in modern engineering.

Share