Feb . 15, 2025 17:32 Back to list

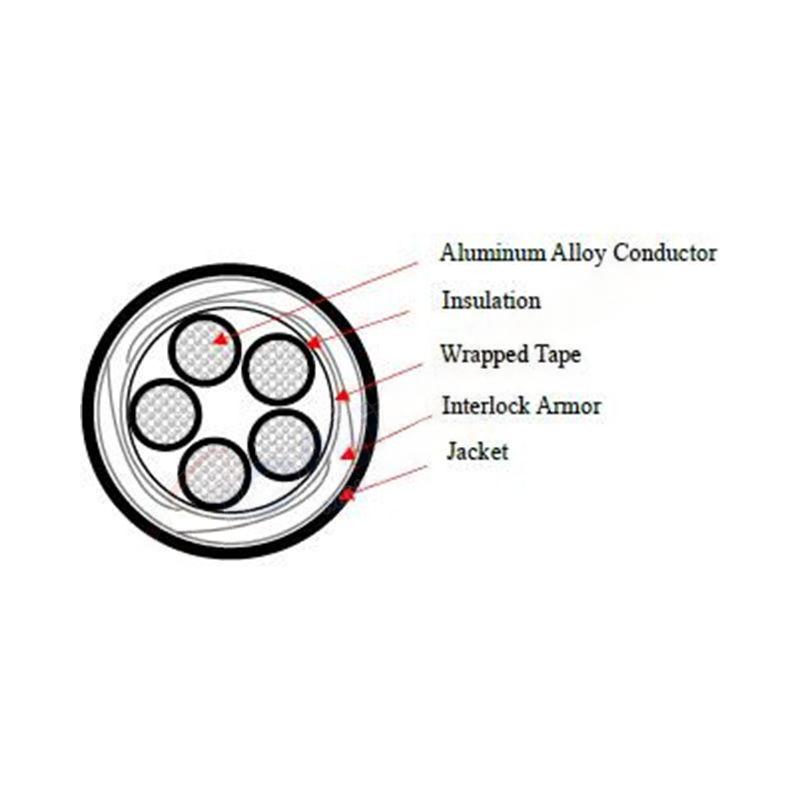

MC ( Type THHN/THWN-2 )

When it comes to enhancing the durability and versatility of wire cables, coated wire cables stand at the forefront of modern engineering solutions. These cables, innovative in their construction, offer a myriad of advantages over their uncoated counterparts, appealing not only to industry experts but also to end-users demanding reliability and efficiency.

Trustworthiness in coated wire cables is derived from rigorous testing and compliance with international standards. Manufacturers must adhere to stringent guidelines during production, ensuring the coating's thickness, bonding strength, and overall quality meet predefined benchmarks. Certifications from recognized bodies not only guarantee performance but also help in building trust among consumers and stakeholders who rely on these cables for their most critical functions. Authoritativeness in the realm of coated wire cables is not merely about knowledge but also about continuous innovation. Industry leaders invest heavily in research and development to improve coating technologies, explore new materials, and refine production techniques. Partnerships with academic institutions and participation in research consortia contribute to advancing the field. Organizations that are active in these areas not only lead the market but also set the standards for quality and performance that others follow. For end-users, selecting coated wire cables involves evaluating several factors including the specific environmental conditions, mechanical stresses, and electrical requirements they will be subjected to. This decision should be informed by comprehensive data and insights provided by manufacturers and industry experts alike. Transparent communication regarding the capabilities and limitations of different coated wire cables fosters informed decision-making, aligning with the principles of trustworthiness. In conclusion, coated wire cables embody a combination of experience, expertise, authoritativeness, and trustworthiness. They current solutions powered by advanced engineering and a deep understanding of real-world applications. Whether used in high-tech industries or daily utilities, these cables represent a convergence of innovation and reliability, tailored to meet the ever-evolving demands of their varied applications.

Trustworthiness in coated wire cables is derived from rigorous testing and compliance with international standards. Manufacturers must adhere to stringent guidelines during production, ensuring the coating's thickness, bonding strength, and overall quality meet predefined benchmarks. Certifications from recognized bodies not only guarantee performance but also help in building trust among consumers and stakeholders who rely on these cables for their most critical functions. Authoritativeness in the realm of coated wire cables is not merely about knowledge but also about continuous innovation. Industry leaders invest heavily in research and development to improve coating technologies, explore new materials, and refine production techniques. Partnerships with academic institutions and participation in research consortia contribute to advancing the field. Organizations that are active in these areas not only lead the market but also set the standards for quality and performance that others follow. For end-users, selecting coated wire cables involves evaluating several factors including the specific environmental conditions, mechanical stresses, and electrical requirements they will be subjected to. This decision should be informed by comprehensive data and insights provided by manufacturers and industry experts alike. Transparent communication regarding the capabilities and limitations of different coated wire cables fosters informed decision-making, aligning with the principles of trustworthiness. In conclusion, coated wire cables embody a combination of experience, expertise, authoritativeness, and trustworthiness. They current solutions powered by advanced engineering and a deep understanding of real-world applications. Whether used in high-tech industries or daily utilities, these cables represent a convergence of innovation and reliability, tailored to meet the ever-evolving demands of their varied applications.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025