Dec . 11, 2024 01:48 Back to list

Durable Cast Iron Gate Valve with Metal Seat for Optimal Performance and Reliability

The Importance of Cast Iron Metal Seat Gate Valves in Modern Infrastructure

In the realm of fluid control systems, gate valves play a pivotal role in regulating the flow of liquids and gases across a variety of applications. Among the different types of gate valves, cast iron metal seat gate valves have garnered attention for their durability, reliability, and cost-effectiveness. This article explores the significance of cast iron metal seat gate valves and their applications in modern infrastructure.

Understanding Gate Valves

Gate valves are specifically designed to allow or obstruct the flow of fluid in a pipeline. They feature a wedge-shaped gate that moves up and down within a valve body, enabling or blocking flow when operated. Gate valves are primarily employed in on/off service, making them ideal for applications where fluid flow needs to be stopped completely or allowed to resume quickly.

What Makes Cast Iron Metal Seat Gate Valves Unique?

Cast iron is well-regarded for its strength and durability, along with its excellent resistance to corrosion, making it an ideal material for a variety of industrial applications. In gate valves, the metal seat provides a robust surface against which the gate seals, ensuring leak-free operation. The combination of cast iron and metal seating enhances the valve's ability to withstand high pressures, temperatures, and abrasive conditions.

1. Durability and Long Lifespan Cast iron components can endure extreme conditions without degrading quickly, which translates to a longer operational life compared to valves made from other materials. This ensures that infrastructure can operate without frequent maintenance or replacement, which is a significant economic advantage.

2. Cost-Effectiveness Cast iron is an economically viable option compared to stainless steel or other alloys. It balances high performance with affordability, making it a preferred choice for numerous applications in waterworks, sewage systems, and industrial operations.

3. Corrosion Resistance The construction of cast iron metal seat gate valves allows for excellent resistance against corrosion, especially when treated. As these valves come into contact with various chemicals and liquids, having a corrosion-resistant material is crucial for maintaining integrity and preventing leakage.

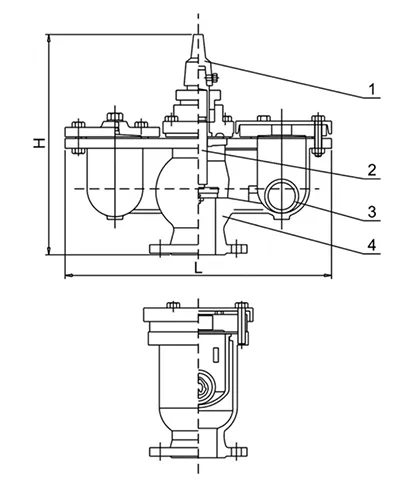

cast iron metal seat gate valve

4. Maintenance and Repair Cast iron valves are relatively easy to maintain. Even if issues arise, repairs can be executed without requiring complete replacement, which further extends the valve's usability and capability in demanding settings.

Applications of Cast Iron Metal Seat Gate Valves

Due to their unique properties, cast iron metal seat gate valves are widely used in various applications

- Water and Wastewater Management These valves are extensively utilized in municipal water supply systems to manage the flow of water, as well as in wastewater treatment facilities to control the discharge and treatment processes.

- Industrial Processes In manufacturing and processing industries, cast iron gate valves are used in piping systems to control fluids, slurries, and other materials, ensuring efficient operation and safety.

- Heating Systems Used in steam and heating applications, these valves help regulate the flow of hot water or steam, maintaining system balance and efficiency.

- Fire Protection Systems In firefighting systems, cast iron gate valves are essential for managing the water supply to hydrants and sprinkler systems, ensuring that adequate pressure is available when needed.

Conclusion

As infrastructure requirements continue to evolve, the relevance of cast iron metal seat gate valves remains paramount. Their durability, affordability, and resistance to adverse conditions make them a viable choice for indispensable applications across various industries. As cities and industries expand and modernization takes place, the demand for reliable fluid control solutions like cast iron metal seat gate valves will only grow, ensuring that they remain a cornerstone of engineering and infrastructure development. Investing in high-quality cast iron metal seat gate valves not only supports the longevity of systems but ultimately contributes to optimizing operational efficiency and safety in a world increasingly reliant on intricate fluid management systems.

Share