Nov . 30, 2024 01:14 Back to list

Flange Connection Options for Ball Valve Applications and Their Benefits

Understanding Ball Valve Flange Types

Ball valves are essential components in various industries, known for their ability to provide a reliable seal and regulate the flow of fluids effectively. When designing a piping system, it's crucial to choose the right type of valve, and one commonly employed design is the flange-type ball valve. This article will delve into the characteristics, advantages, and considerations of ball valve flange types.

What is a Flange-Type Ball Valve?

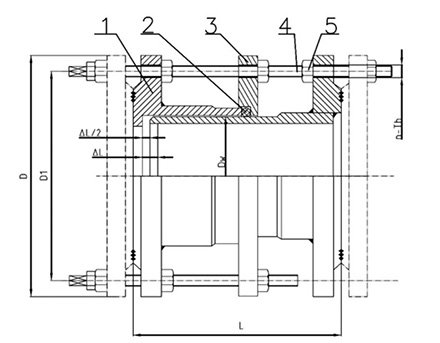

A flange-type ball valve incorporates flanges at both ends, allowing for easy installation and secure connections to the piping system. The valve body is typically made from materials such as stainless steel, brass, or carbon steel, depending on the application requirements. These valves consist of a hollow, perforated ball that rotates within the valve body to control the flow of the media. When the ball's hole aligns with the flow direction, the valve is open; when it is perpendicular, the valve is closed.

Types of Flanges

Flange connections come in various types, the most common being

1. Weld Neck Flanges With a long neck that gradually tapers to the pipe's diameter, weld neck flanges are ideal for high-pressure applications. They allow for a strong connection through welding, which is essential for maintaining integrity in demanding environments.

2. Slip-On Flanges These flanges are designed to slip over the pipe. They are easier to install and require less welding than weld neck flanges. However, they may not provide the same level of strength under high-pressure conditions.

3. Blind Flanges Used to seal the end of a piping system, blind flanges provide a strong closure without an opening. They are often used in applications where future access may be necessary.

4. Threaded Flanges These flanges are ideal in situations where welding is not an option. They are screwed onto the pipe, making them suitable for low-pressure applications. However, threaded flanges generally have lower pressure ratings compared to welded ones.

Advantages of Flange-Type Ball Valves

1. Easy Installation and Maintenance Flange-type ball valves can be easily installed and removed, making them an ideal choice for systems that require frequent maintenance or modification. Their design allows for straightforward disassembly without the need for specialized tools.

ball valve flange type

2. High Flow Capacity Due to the spherical design of the valve, there is minimal resistance to the flow of fluids, which results in a high flow capacity. This feature is particularly beneficial in applications where maintaining pressure and flow rates is critical.

3. Reliable Sealing Ball valves are known for their excellent sealing capabilities. The tight contact between the ball and the seat prevents leaks, making them suitable for both liquid and gas applications.

4. Versatility These valves can handle a wide range of temperatures and pressures. Ensure you select a material that can withstand the specific conditions of your application.

Considerations When Choosing a Flange-Type Ball Valve

While flange-type ball valves offer several advantages, there are also important considerations to keep in mind

1. Size It's crucial to select the correct size of the valve to ensure optimal performance. The size will determine the flow rate and pressure drop within the system.

2. Material Compatibility Depending on the fluid being transported, the material of the valve must be compatible to prevent corrosion or degradation. For example, aggressive chemicals may require specific alloys or coatings.

3. Pressure Ratings Ensure the chosen valve can handle the pressure requirements of the system. Each valve type has specific pressure ratings, and exceeding these can lead to failure.

4. Installation Environment Assess the environmental conditions where the valve will be installed, including ambient temperature and exposure to chemicals, to choose the appropriate valve type and materials.

Conclusion

Flange-type ball valves are a popular choice in numerous applications due to their ease of installation, reliable sealing, and versatility. By understanding the different flange types and their advantages, as well as considering key factors such as size, material compatibility, and pressure ratings, you can make informed decisions that ensure the efficiency and safety of your piping systems. Investing in quality ball valves will ultimately lead to enhanced performance and longevity in fluid handling applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025