Nov . 14, 2024 23:56 Back to list

1600mm butterfly valve

Understanding the 1600mm Butterfly Valve Key Features and Benefits

In the world of industrial fluid control, valves play a crucial role in regulating the flow of liquids and gases. Among the various types of valves, the butterfly valve stands out for its versatility, reliability, and efficiency. Specifically, the 1600mm butterfly valve has garnered attention in various applications due to its unique specifications and capabilities. This article explores the key features, benefits, and applications of the 1600mm butterfly valve.

Design and Construction

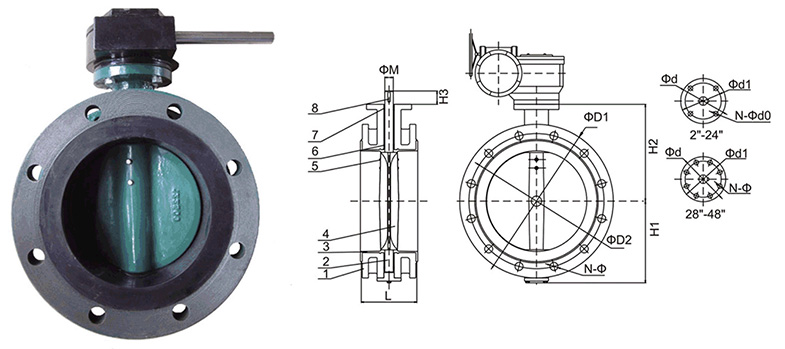

A butterfly valve is characterized by a disc that rotates around a central axis to control the flow of fluid. The 1600mm butterfly valve, with a diameter of 1600 millimeters, is a large valve often utilized in systems requiring substantial flow rates. Its design typically involves a sturdy body, often made of ductile iron, stainless steel, or carbon steel, which can handle high pressures and harsh environments. The disc is usually coated with materials like EPDM, NBR, or Viton, which enhance its durability and resistance to corrosion.

One of the significant advantages of the butterfly valve's design is its compactness. Unlike gate valves that require a large space to fully open or close, the butterfly valve's mechanism allows for quicker actuation, making it ideal for scenarios where fast response times are critical.

Operational Efficiency

The operational efficiency of the 1600mm butterfly valve is noteworthy. The valve’s disc has minimal resistance when it is opened, reducing the required torque for operation. This characteristic not only saves energy but also leads to less wear and tear on the actuators and other components. The butterfly valve can be operated manually with handwheels or automatically using electric, pneumatic, or hydraulic actuators, making it suitable for both small-scale and large-scale applications.

Furthermore, the flow control provided by a butterfly valve is highly efficient. It allows for throttling and tight shut-off, which is essential in many industrial processes. The design of the valve ensures that it can maintain a consistent flow rate while minimizing turbulence and pressure drops within the system.

1600mm butterfly valve

Applications

The versatility of the 1600mm butterfly valve makes it suitable for a wide range of applications across different industries. It is commonly used in

1. Water Treatment Plants Due to their ability to handle large volumes of water, butterfly valves are vital in controlling flow within treatment processes. 2. Chemical Processing Their resistance to corrosive materials makes them ideal for managing the flow of various chemicals, ensuring safety and efficiency.

3. Oil and Gas Butterfly valves can manage the flow of crude oil and natural gas in pipelines, where their robust design can withstand varying pressures.

4. HVAC Systems In heating, ventilation, and air conditioning systems, these valves help regulate airflow, enhancing overall system efficiency.

5. Fire Protection Systems They provide reliable flow control necessary for effective firefighting measures.

Conclusion

In summary, the 1600mm butterfly valve is a crucial component in modern industrial applications, offering robustness, efficiency, and versatility. Its compact design coupled with its ability to operate effectively under high pressures and varied conditions makes it an essential tool across various sectors. Understanding its features and applications can help professionals make informed decisions when it comes to fluid management in their respective industries. As technology advances, the ongoing development in valve design continues to enhance performance and reliability, ensuring that the butterfly valve remains a critical element in industrial fluid control systems for years to come.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025