Nën . 20, 2024 22:35 Back to list

rising stem gate valve

Understanding Rising Stem Gate Valves A Comprehensive Overview

Rising stem gate valves are critical components in various industrial applications, particularly in the oil and gas, water treatment, and chemical processing sectors. This article aims to provide a detailed understanding of rising stem gate valves, including their design, functioning, applications, advantages, and maintenance considerations.

What is a Rising Stem Gate Valve?

A rising stem gate valve is a type of valve that uses a sliding gate to control the flow of fluids. The primary feature that distinguishes this valve from others is its stem, which rises or lowers as the valve is opened or closed. This design allows for visual confirmation of the valve position, enhancing operational safety and facilitating maintenance procedures. The gate itself can be either a solid wedge or a knife gate, depending on the application's pressure and temperature requirements.

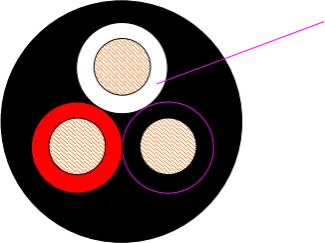

Design and Components

The basic components of a rising stem gate valve include the body, gate, stem, handwheel or actuator, and sealing elements. The body is typically made from materials like cast iron, stainless steel, or brass, depending on the temperature and pressure conditions. The gate is designed to create a tight seal when fully closed, preventing any leakage. The stem connects the gate to the actuator, providing the necessary motion to open or close the valve.

One of the most significant advantages of the rising design is that it helps to isolate the gate from the flow of media, which minimizes wear and prolongs the valve’s life. Additionally, the visible rising stem allows operators to quickly assess whether the valve is fully opened or closed, enabling better management of flow control.

Functional Mechanics

When the handwheel is turned or the actuator is engaged, the stem moves vertically within the valve body. As the stem rises, it pulls the gate upward, creating a passage for the fluid to flow. Conversely, when the valve is closed, the stem moves downward to push the gate back into its sealing position.

The operation can be either manual or automated. Manual rising stem gate valves require a handwheel, while automated versions can be connected to electric or pneumatic actuators for remote operation. This flexibility makes rising stem gate valves suitable for various operational needs and environments.

rising stem gate valve

Applications

Rising stem gate valves are commonly used in situations where a full-open or full-closed position is desired. They are ideal for applications involving high-pressure and high-temperature fluids. Common usages include

1. Water Supply Systems To control the supply and distribution of water in municipal systems. 2. Oil and Gas To manage flow in pipelines and during extraction processes. 3. Chemical Processing To safely isolate and control chemical flow, protecting critical equipment from contamination. 4. Power Plants To regulate steam and cooling water flow in various operational stages.

Advantages

Rising stem gate valves offer several advantages

- Visual Confirmation The rising stem allows operators to easily identify the valve’s status, enhancing operational safety. - Minimal Flow Resistance When fully open, the gate is out of the flow path, providing minimal resistance and reducing turbulence. - Simple Design With fewer moving parts compared to other valve types, maintenance is generally straightforward. - Durability Rising stem gate valves can withstand harsh operating conditions, where other valves may fail.

Maintenance Considerations

While rising stem gate valves are known for their durability, routine maintenance is essential to ensure long-term functionality. Operators should periodically inspect the valve for signs of wear or damage, particularly on the stem threads and sealing surfaces. Lubrication of the stem is crucial to prevent corrosion and facilitate smooth operation. Additionally, regular testing for leaks is recommended to maintain safety standards, particularly in critical applications.

Conclusion

Rising stem gate valves are essential for efficient fluid control in various industries. Their unique design, coupled with distinct advantages like operational safety and minimal flow resistance, makes them a popular choice among engineers and operators. By understanding their functionality, applications, and maintenance needs, industry professionals can make informed decisions when selecting the right valve for their systems, ensuring reliability and efficiency in fluid handling processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025