Nën . 12, 2024 17:59 Back to list

mss metal seat gate valve

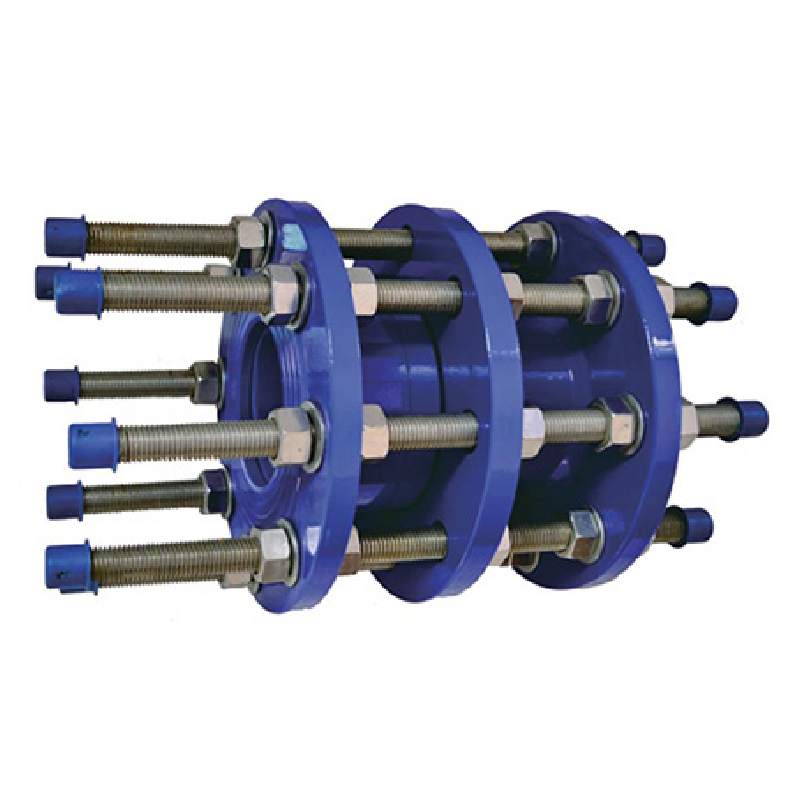

Understanding MSS Metal Seat Gate Valves

MSS (Manufacturers Standardization Society) metal seat gate valves are essential components in various industrial applications where fluid control is critical. These valves are designed to provide a reliable and effective means of isolating flow, making them a popular choice for industries such as oil and gas, water treatment, and chemical processing. This article delves into the details of MSS metal seat gate valves, exploring their design, functionality, benefits, and applications.

What is a Metal Seat Gate Valve?

A metal seat gate valve is a type of valve that operates by lifting a gate out of the flow path when the valve is opened, allowing fluid to flow through. The unique aspect of the metal seat design incorporates metal components in the seating area to improve durability and performance under high-temperature and high-pressure conditions. This contrasts with traditional gate valves, which may utilize softer materials like rubber or plastic for seating.

Design and Construction

MSS metal seat gate valves are manufactured according to the stringent standards set by the Manufacturers Standardization Society, ensuring quality and consistency. The design typically includes

1. Body and Bonnet Made from robust materials such as carbon steel, alloy steel, or stainless steel to withstand harsh environments. 2. Gate The gate is usually made of the same material as the body to ensure strength and corrosion resistance. 3. Seating Area The metal seats are often designed with precision to achieve a tight seal when the valve is closed, preventing any leakage. 4. Stem The stem, usually constructed from durable materials, connects the handwheel or actuator to the gate, facilitating smooth operation.

MSS metal seat gate valves can be operated manually or automatically using actuators, depending on the application requirements

.Functionality

mss metal seat gate valve

Metal seat gate valves are characterized by their linear flow path, which minimizes resistance and pressure drop when the valve is fully open. The primary function of these valves is to provide a reliable shut-off mechanism. When fully closed, the gate creates a tight seal against the metal seat, preventing leakage. When the valve is opened, the gate lifts away from the seat, allowing for unrestricted flow, making them suitable for applications requiring a quick isolation or diversion of fluid.

Benefits of MSS Metal Seat Gate Valves

1. Durability The use of metal seating increases the lifespan of the valve, especially in environments with high temperatures or abrasive materials. 2. Leakage Prevention The tight seal provided by the metal seat design significantly reduces the chances of leakage. 3. Versatility These valves can be used in a wide range of applications, from water transportation to high-pressure gas systems. 4. Minimal Pressure Drop The design allows for a smooth flow path, ensuring minimal pressure loss in the system. 5. Ease of Operation Manual or automated, these valves provide reliable performance with less effort than other valve types.

Applications

MSS metal seat gate valves find applications in diverse industries, including

- Oil and Gas Utilized for flow control in pipelines and refineries, where high pressures and temperatures are common. - Water Treatment Essential for isolating sections of piping in water supply systems. - Chemical Processing Employed in systems handling corrosive and hazardous materials. - Power Generation Used in cooling water systems and steam lines to regulate flow.

Conclusion

MSS metal seat gate valves are integral to efficient and safe fluid control in various industrial sectors. Their robust design, combined with the benefits of metal seating, ensures they withstand the rigors of demanding operational environments. As industries continue to evolve, the reliability and effectiveness of MSS metal seat gate valves will remain a critical component in maintaining the flow of various fluids and ensuring operational efficiency. Understanding these valves' design and functionality can greatly assist engineers and operators in selecting the right valves for their specific applications, ultimately leading to enhanced performance and safety in industrial operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025