Jan . 20, 2025 16:33 Back to list

Ball Check Valve

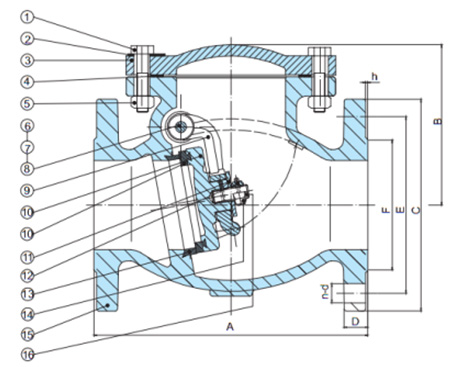

In the realm of fluid control and piping systems, the double ball check valve stands as a pivotal component, having captured the trust of engineers and technicians worldwide. Known for its robustness and reliability, this type of valve is crucial for ensuring the smooth operation of systems that require precise control and management of fluid flow. This article seeks to deliver a comprehensive, insightful look into the functionality, application, and inherent advantages of double ball check valves, with an emphasis on practical experience and technical authority.

Real-world experiences highlight the tangible benefits of deploying double ball check valves in a variety of settings. Reports from field technicians often emphasize the reduction in energy consumption due to the valve’s efficient operation. By preventing backflow effectively, these valves maintain optimal pressure in systems, thus reducing the need for additional pumping energy. This aspect not only optimizes system performance but also contributes to sustainability goals by lowering the carbon footprint. In addition, the installation and maintenance of double ball check valves are relatively straightforward, thanks to their compact and user-friendly design. This simplicity translates to reduced labor costs and shorter downtime. Skilled technicians have praised these valves for their longevity and minimal maintenance needs. When maintenance is required, the design allows for quick access and servicing, ensuring that operations can resume with minimal disruption. When considering the trustworthiness of double ball check valves, the experiences of companies across sectors should not be overlooked. Long-term field data and feedback verify the valve's reliability and robustness. Clients consistently report high satisfaction rates, citing fewer failures and maintenance issues compared to alternative solutions. In conclusion, double ball check valves combine reliability, efficiency, and ease of use, making them a cornerstone in fluid management systems. Their continued adoption across industries underscores their significance and capability, reflecting a harmonious blend of engineering excellence and practical utility. When performance and dependability are non-negotiable, betting on the time-tested double ball check valve is a decision grounded in sound engineering judgment and a commitment to quality.

Real-world experiences highlight the tangible benefits of deploying double ball check valves in a variety of settings. Reports from field technicians often emphasize the reduction in energy consumption due to the valve’s efficient operation. By preventing backflow effectively, these valves maintain optimal pressure in systems, thus reducing the need for additional pumping energy. This aspect not only optimizes system performance but also contributes to sustainability goals by lowering the carbon footprint. In addition, the installation and maintenance of double ball check valves are relatively straightforward, thanks to their compact and user-friendly design. This simplicity translates to reduced labor costs and shorter downtime. Skilled technicians have praised these valves for their longevity and minimal maintenance needs. When maintenance is required, the design allows for quick access and servicing, ensuring that operations can resume with minimal disruption. When considering the trustworthiness of double ball check valves, the experiences of companies across sectors should not be overlooked. Long-term field data and feedback verify the valve's reliability and robustness. Clients consistently report high satisfaction rates, citing fewer failures and maintenance issues compared to alternative solutions. In conclusion, double ball check valves combine reliability, efficiency, and ease of use, making them a cornerstone in fluid management systems. Their continued adoption across industries underscores their significance and capability, reflecting a harmonious blend of engineering excellence and practical utility. When performance and dependability are non-negotiable, betting on the time-tested double ball check valve is a decision grounded in sound engineering judgment and a commitment to quality.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025