Dhj . 11, 2024 07:05 Back to list

ball check valve

The Importance and Functionality of Ball Check Valves

Ball check valves are a critical component in a wide range of fluid systems, providing reliable performance in preventing backflow and ensuring the proper operation of various applications. Their unique design offers both reliability and efficiency, making them indispensable in many industrial and commercial settings. This article will explore the operational principles, applications, benefits, and maintenance of ball check valves.

Understanding Ball Check Valves

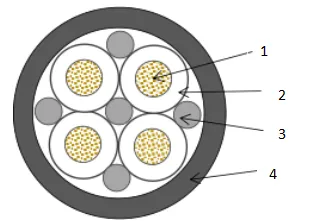

A ball check valve consists of a spherical float, typically made from materials like stainless steel, plastic, or brass, which rests in a seat within the valve body. This sphere functions as a one-way barrier, allowing fluid to flow in only one direction. When the fluid flows in the intended direction, the ball is lifted from its seat, allowing free passage. Conversely, if the fluid attempts to flow backward, the ball is forced back against the seat, effectively sealing the valve and preventing reverse flow. This mechanism provides a reliable solution for managing fluid dynamics in various systems.

Applications of Ball Check Valves

Ball check valves are versatile and widely used in many industries. One of their main applications is in water and wastewater management systems. In these systems, they help control the flow of water and prevent contamination or backflow, which can cause significant health risks and operational inefficiencies. Additionally, ball check valves are commonly utilized in irrigation systems to ensure that water flows in the desired direction, enhancing the effectiveness of agricultural operations.

Another significant application is in the oil and gas industry, where these valves prevent the backflow of hydrocarbons, ensuring that transportation and processing systems remain safe and efficient. Similarly, in HVAC (Heating, Ventilation, and Air Conditioning) systems, ball check valves are crucial for maintaining proper air and fluid flow, contributing to energy efficiency and system reliability.

Benefits of Ball Check Valves

ball check valve

The design of ball check valves offers several advantages. Firstly, their simple structure ensures easy installation and maintenance. Compared to other types of check valves, such as swing or diaphragm check valves, ball check valves have fewer moving parts, reducing the likelihood of mechanical failure.

Moreover, ball check valves provide excellent sealing capabilities. The design ensures that even under varying pressure conditions, the ball remains seated and prevents backflow effectively. This reliability is vital in maintaining system integrity and protecting sensitive components from potential damage caused by reverse flow.

Another benefit is their versatility. Ball check valves can be used for various fluids, including water, oil, and even some corrosive substances, depending on the materials used in their construction. The ability to adapt to different environments makes them a favorable choice for many applications.

Maintenance and Operational Considerations

While ball check valves are designed for durability and reliability, regular maintenance is crucial to ensure optimal performance. Routine inspections should be conducted to check for any signs of wear or damage, especially in high-pressure applications. Ensuring that the valve remains clear of debris and buildup is essential in maintaining its sealing capability and overall functionality.

In terms of operational considerations, it is essential to install ball check valves in the correct orientation. They should be positioned to allow fluid flow in the intended direction, as improper installation can lead to inefficient performance or even failure.

Conclusion

In summary, ball check valves play an essential role in fluid management systems across various industries. Their unique design, reliability, and versatility make them a preferred choice for applications requiring effective backflow prevention. By understanding their functionality and maintaining them appropriately, businesses can enhance operational efficiency and ensure the integrity of their systems. As industries continue to evolve, the significance of ball check valves will undoubtedly remain paramount in the realm of fluid dynamics.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025