Dec . 24, 2024 16:56 Back to list

Understanding Wafer Style Butterfly Valves for Efficient Flow Control and Installation

Understanding Wafer Style Butterfly Valves A Comprehensive Overview

In the world of fluid control systems, valves play a pivotal role, and among these, the wafer style butterfly valve stands out for its efficiency and versatility. This type of valve is widely used in various industrial applications, ranging from water treatment plants to chemical processing facilities, primarily due to its compact design and effective performance in regulating flow.

Design and Structure

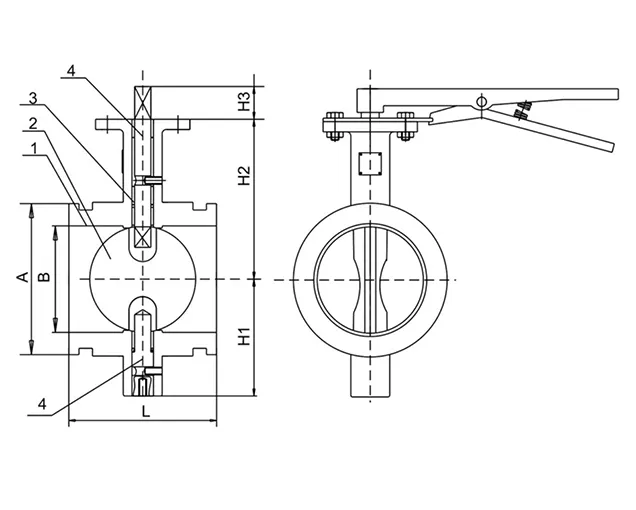

Wafer style butterfly valves are distinguished by their unique construction. They consist of a circular disc or butterfly that pivots on a shaft. This disc is positioned in the center of the valve body and can rotate to either allow or restrict flow. The term wafer refers to the valve's design that fits between two flanges, enabling it to be easily installed in a pipeline without requiring extensive modifications or additional supports. This flange-less design promotes a lightweight and compact element, making it especially suitable for tight spaces.

The body of a wafer style butterfly valve is typically made of durable materials such as cast iron, stainless steel, or PVC, depending on the application and the type of fluid being controlled. The choice of material is crucial, as it affects the valve's resistance to corrosion, pressure, and temperature fluctuations. The sealing mechanism often consists of elastomeric seats or metal-to-metal sealing surfaces, providing flexibility and reliability in performance.

Operational Efficiency

One of the most significant advantages of wafer style butterfly valves is their operational efficiency. The design allows for a full open/close function with minimal pressure drop when fully open, thus ensuring optimal flow rates. This characteristic is particularly beneficial in systems where maintaining pressure and fluid velocity is crucial.

Moreover, the quick-actuation feature of butterfly valves—typically requiring only a quarter-turn to transition between open and closed positions—enhances the speed of operation. This quick responsiveness is vital in emergency situations where rapid flow control is necessary to prevent accidents or mitigate risks.

wafer style butterfly valve

Versatility in Applications

Wafer style butterfly valves are versatile and can be used in various applications across different industries. They are commonly found in

- Water and Wastewater Treatment Their ability to handle large volumes of fluid with low flow resistance makes them ideal for pumping stations and treatment plants. - HVAC Systems Butterfly valves are utilized for controlling airflow and maintaining temperature control in heating and cooling systems. - Chemical Processing The corrosion-resistant models withstand harsh chemicals, making them essential in chemical plants and refineries. - Food and Beverage Industries Sanitary versions of these valves ensure compliance with industry standards while facilitating the flow of liquids in production lines.

Advantages Over Other Valve Types

Compared to other valve types, such as gate or globe valves, wafer style butterfly valves offer several advantages. Their lightweight and compact design make them easier to handle and install, significantly reducing installation time and costs. Additionally, the lower torque required to operate a butterfly valve translates into less wear on the valve components and reduced power consumption when automated systems are used.

Furthermore, the maintenance requirements for wafer style butterfly valves are lower than for many other valve types. Their straightforward construction and fewer moving parts mean that there are fewer points of potential failure, ultimately leading to increased reliability and reduced downtime in industrial operations.

Conclusion

In conclusion, wafer style butterfly valves represent a fusion of efficiency, versatility, and cost-effectiveness in fluid control applications. Their unique design, operational features, and suitability for various applications have made them a staple in many industries. As technology evolves, we can expect further innovations in butterfly valve design, enhancing their capabilities and expanding their applications in an increasingly complex industrial landscape. For anyone involved in fluid management or control systems, understanding and appreciating the role of wafer style butterfly valves is essential for optimizing performance and efficiency in their operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025