Nov . 06, 2024 07:10 Back to list

Exploring the Advantages of U Type Butterfly Valves in Industrial Applications

Understanding U-Type Butterfly Valves A Comprehensive Overview

The U-type butterfly valve is a pivotal component in many industrial applications, particularly in the realm of fluid control. Due to its unique design and functionality, this valve type is favored for its efficiency, reliability, and versatility in various environments. In this article, we will delve into the specifications, working principle, advantages, installations, and applications of U-type butterfly valves.

What is a U-Type Butterfly Valve?

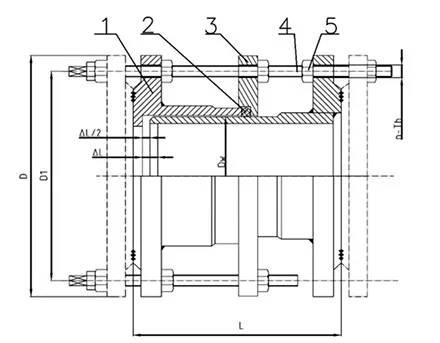

A U-type butterfly valve is characterized by its circular disc that rotates on a horizontal axis, allowing for quick and precise control of fluid flow within a pipeline. The U designation refers to the shape of the valve body and the design philosophy aimed at maximizing performance while minimizing resistance to flow.

Working Principle

The operation of a U-type butterfly valve relies on the rotation of the disc. When the valve is fully open, the disc aligns with the flow path, allowing fluid to pass unobstructed. Conversely, when the disc is rotated to a closed position, it blocks the flow, creating a seal within the pipeline. This simple yet effective mechanism enables rapid shut-off and control of the fluid, making it ideal for various applications.

Design Features

1. Body Material U-type butterfly valves are available in various materials, including stainless steel, cast iron, and PVC. The choice of material often depends on the type of fluid being transported and the environmental conditions.

2. Sealing Mechanism Many U-type butterfly valves utilize elastomeric seals or metal seats to ensure a tight shut-off and prevent leakage. The choice of sealing mechanism plays a critical role in the valve's performance and longevity.

3. Size Variability These valves come in various sizes, ranging from small diameters suitable for low-flow applications to large diameters designed for substantial industrial systems. This size versatility enables their use in diverse applications.

Advantages of U-Type Butterfly Valves

2. Low Operating Torque The design requires minimal force to operate the valve, which translates to lower gear and actuator requirements. This feature significantly reduces energy consumption and costs in operating the valve.

u type butterfly valve

3. Minimal Pressure Drop The streamlined design of the U-type butterfly valve contributes to minimal resistance to fluid flow, ensuring efficient performance and maintaining pressure levels within the system.

4. Ease of Maintenance U-type butterfly valves require less maintenance compared to other valve types due to their straightforward and robust design. This advantage saves both time and resources for industries reliant on consistent fluid control.

Installation Considerations

Proper installation of U-type butterfly valves is essential for optimal performance. Factors such as pipe alignment, torque requirements, and the orientation of the valve can significantly impact functionality. Installing the valve in the correct orientation—typically horizontal—in conjunction with suitable mounting helps achieve optimal performance.

Applications

U-type butterfly valves are employed across numerous industries, including

- Water Treatment They are used in various processes, including filtration, distribution, and chemical dosing. - Oil and Gas U-type butterfly valves are crucial for controlling the flow of hydrocarbons and other fluids in pipelines.

- Food and Beverage These valves meet stringent hygiene standards, making them suitable for fluid handling in processing plants.

- HVAC Systems They regulate airflow and provide shut-off capabilities in heating, ventilation, and air conditioning systems.

- Chemical Processing Their ability to handle corrosive liquids makes them a preferred choice in chemical plants.

Conclusion

The U-type butterfly valve represents an efficient, reliable, and versatile solution for fluid control in various industrial applications. By understanding its working principles, advantages, and suitable installation practices, engineers and technicians can optimize their use in various systems, ensuring maximum efficiency and longevity. As industries continue to evolve, the role of U-type butterfly valves will undoubtedly remain significant in facilitating the efficient movement of fluids.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025