Nov . 07, 2024 14:48 Back to list

Price Comparison for Rubber Expansion Joints in the Market Today

Understanding the Pricing of Rubber Expansion Joints

Rubber expansion joints are essential components in various piping systems, designed to absorb vibrations, reduce noise, and compensate for thermal expansion and contraction. With their increasing applications in numerous industries, including construction, manufacturing, and water treatment, understanding the factors that influence their pricing is crucial for consumers and businesses alike.

What are Rubber Expansion Joints?

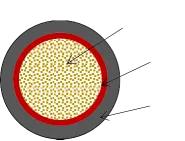

Rubber expansion joints are flexible connectors made from elastomeric materials, which allow for movement in piping systems. They are engineered to accommodate shifts caused by temperature changes or mechanical vibrations, thereby helping to maintain the integrity of the piping. These joints are often used in systems that transport fluids or gases, such as water, steam, and oil.

Factors Influencing Pricing

The price of rubber expansion joints can vary significantly based on several key factors

1. Material Quality The type of rubber used to manufacture the expansion joint plays a significant role in its pricing. High-quality, durable materials like EPDM, Neoprene, and Silicone are generally more expensive due to their superior resistance to temperature extremes, chemicals, and physical wear.

2. Size and Dimensions Larger expansion joints require more material and often cost more. Custom sizes and shapes, which are tailored to specific applications, also come with a premium price tag compared to standard sizes.

3. Design Complexity More complex designs that incorporate additional features, such as internal flow liners or special reinforcement layers, can significantly increase the cost. These features enhance performance characteristics, particularly in high-pressure or high-temperature applications.

rubber expansion joint price

4. Manufacturing Process The manufacturing techniques used can affect pricing. Joints produced using advanced technologies or in compliance with strict quality standards may carry higher costs due to increased production efficiency and quality assurance.

5. Brand Reputation Well-established manufacturers with a reputation for quality and reliability often charge more for their products. This premium reflects both the trust and assurance that come with buying from recognized brands with a history of success in the industry.

6. Economies of Scale Bulk purchasing can lead to significant savings. Companies that require large quantities of rubber expansion joints may negotiate better prices than those purchasing smaller quantities. Additionally, distributors may offer discounts for larger orders.

7. Market Demand and Supply Just like any other product, the prices of rubber expansion joints can fluctuate based on market demand and supply. Factors such as seasonal changes in construction activity or disruptions in the supply chain can influence prices.

Cost-Benefit Analysis

When considering the price of rubber expansion joints, it is vital to perform a cost-benefit analysis. While cheaper alternatives are available, compromising on quality can lead to increased maintenance costs and potential system failures. A high-quality rubber expansion joint, though more expensive upfront, can provide greater longevity, reduced downtime, and improved operational efficiency.

Conclusion

In summary, the pricing of rubber expansion joints is influenced by several interconnected factors including material quality, size, design complexity, manufacturing processes, and market dynamics. Understanding these elements can help buyers make informed purchasing decisions. It’s essential for businesses to weigh the initial costs against long-term reliability and performance to ensure they invest wisely. By opting for quality, businesses can avoid frequent replacements and minimize operational disruptions, ultimately leading to cost savings over the lifespan of their piping systems.

Share