Sep . 29, 2024 02:41 Back to list

Understanding the Functionality of Non-Return Swing Check Valves in Plumbing Systems

Understanding Non-Return Swing Check Valves

Check valves serve a vital function in fluid systems by preventing backflow, ensuring that fluids move in the desired direction. Among the various types of check valves, the non-return swing check valve is a common choice due to its simple design and effective mechanism. This article delves into the workings, advantages, applications, and maintenance considerations of non-return swing check valves.

What is a Non-Return Swing Check Valve?

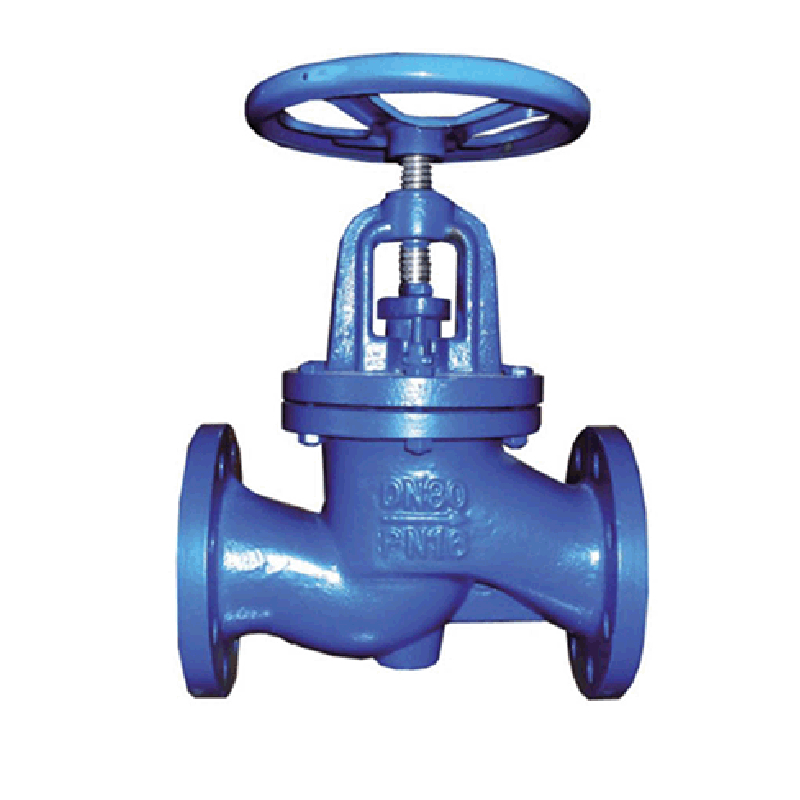

A non-return swing check valve, also known simply as a swing check valve, is a type of valve that automatically prevents backflow in piping systems. It operates with a disc that swings on a hinge or pivot, allowing fluid to flow in one direction while acting as a barrier against reverse flow. This design is particularly effective in applications with water, oil, and steam.

The operational mechanism is straightforward when fluid flows in the forward direction, it lifts the disc away from its seat. Conversely, if the flow tries to reverse, the pressure causes the disc to swing back and close against the seat, blocking any reverse flow. The simplicity of this design is one of the reasons for its widespread use in various industries.

Advantages of Non-Return Swing Check Valves

1. Simple Design The straightforward mechanism of swing check valves contributes to reliability and ease of maintenance. There are fewer moving parts compared to other types of check valves, which minimizes the risk of mechanical failure.

2. Low Pressure Drop Swing check valves offer a low pressure drop across the valve, which is advantageous in fluid systems. This characteristic helps in maintaining the efficiency of the system.

3. Durability Made from robust materials such as metal or corrosion-resistant alloys, swing check valves can withstand various operating conditions, including high pressure and temperature.

4. Versatility They can be used in a wide range of applications, including water treatment, wastewater management, and various industrial processes. This versatility makes them a valuable asset in fluid handling systems.

Applications of Non-Return Swing Check Valves

Due to their efficient operation and reliability, non-return swing check valves find applications in multiple sectors

non return swing check valve

- Water Supply Systems They are commonly used in municipal water systems to prevent backflow and protect potable water from contamination.

- Wastewater Treatment In sewage systems, swing check valves help manage flows and prevent backflow into treatment plants, ensuring proper operation and safety.

- Chemical Processing Their durable construction makes them suitable for handling various chemicals, minimizing the risk of leaks and environmental contamination.

- Heating and Cooling Systems In HVAC applications, swing check valves help maintain proper flow direction, enhancing system efficiency.

Maintenance Considerations

Regular maintenance is crucial to ensure the optimal performance of non-return swing check valves. Here are some key maintenance tips

1. Inspection Periodically inspect the valve for signs of wear, corrosion, and debris accumulation, as clogs can prevent the disc from closing properly.

2. Cleaning Ensure that the valve seat and disc are clean. Any buildup can impair the valve's function and lead to leaks.

3. Testing Regularly test the valve's operation by observing whether it effectively prevents backflow under normal operating conditions.

4. Replacement If the valve shows significant wear or failure, it should be replaced promptly to maintain system integrity.

Conclusion

Non-return swing check valves are indispensable in many fluid systems due to their simple design, effectiveness, and versatility. They not only help prevent backflow but also contribute to the overall efficiency and safety of various applications. By understanding their operation and maintenance needs, operators can ensure these valves perform optimally, safeguarding against costly setbacks in both domestic and industrial settings.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025