Nov . 27, 2024 09:37 Back to list

Optimizing High-Efficiency Butterfly Valves for Superior Performance in Industrial Applications

High Performance Butterfly Valves An Overview

In industrial applications where flow control is crucial, high performance butterfly valves have emerged as a popular choice for their reliability, efficiency, and versatility. These valves are specifically designed to manage the flow of liquids and gases in various sectors, including oil and gas, water treatment, chemical processing, and HVAC systems. The increasing demand for efficient fluid dynamics has propelled the development and adoption of these innovative components.

Understanding Butterfly Valves

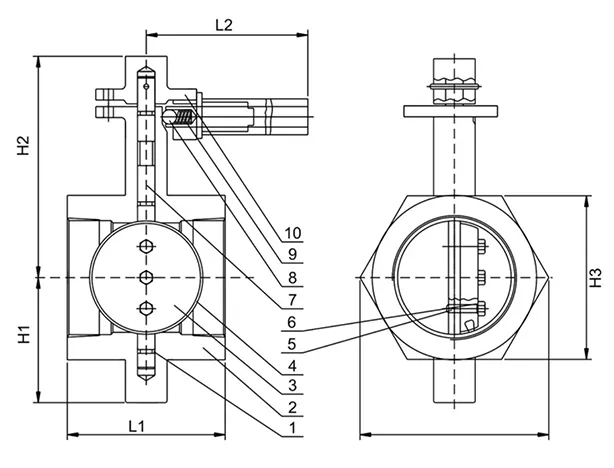

A butterfly valve consists of a circular disc or vane that rotates around a central axis, allowing it to open or close the flow path. The simplicity of this design is one of its significant advantages. Unlike traditional valves, which may feature complex mechanisms, butterfly valves operate with a straightforward quarter-turn motion that minimizes the risk of mechanical failures.

Butterfly valves can be categorized into two primary types soft-seated and metal-seated. Soft-seated valves typically feature a rubber or elastomer lining that provides a tight seal, making them suitable for applications involving low-pressure environments and clean fluids. On the other hand, metal-seated butterfly valves are designed to handle high temperatures and pressures, as they are built with durable materials that can withstand harsh conditions.

Advantages of High Performance Butterfly Valves

One of the key benefits of high performance butterfly valves is their efficiency in handling large volumes of flow. With a streamlined design, they can achieve a low-pressure drop, which is essential in systems where energy conservation is paramount. Additionally, the lightweight nature of these valves reduces the burden on supporting structures, making them ideal for installations where weight is a concern.

Another significant advantage is their adaptability. High performance butterfly valves are available in various materials, including stainless steel, cast iron, and plastic, enabling them to be used in diverse applications. This flexibility allows engineers to select the most suitable valve for specific operational requirements, ensuring optimal performance across different environments.

high performance butterfly valve

Enhanced Control and Automation

The integration of advanced technologies has further enhanced the functionality of butterfly valves. Modern high performance butterfly valves can be equipped with automated actuators, allowing for precise control over flow rates and reducing the need for manual intervention. This level of automation is especially beneficial in processes where consistent flow control is critical, such as in chemical reactions or high-volume fluid delivery systems.

Moreover, many high performance butterfly valves come with advanced feedback systems, providing real-time data on flow conditions and valve status. This capability allows for predictive maintenance and reduces downtime, contributing to better overall system efficiency.

Industries Benefiting from High Performance Butterfly Valves

The versatility of high performance butterfly valves makes them suitable for a wide array of industries. In the oil and gas sector, they are used in pipelines and refineries for effective flow management. In water treatment facilities, butterfly valves play a critical role in controlling the distribution of treated water. Chemical processing plants rely on these valves to manage corrosive and abrasive materials.

Furthermore, HVAC systems benefit from the energy efficiency of butterfly valves, optimizing airflow and temperature control in building environments. Their ability to handle varying pressures and temperatures makes them a reliable choice for commercial and residential applications alike.

Conclusion

High performance butterfly valves represent a pivotal advancement in flow control technology. Their efficient design, adaptability to various conditions, and integration with automated systems make them an indispensable component in numerous industrial applications. As industries continue to seek innovative solutions for improved performance and energy efficiency, high performance butterfly valves are poised to remain at the forefront of fluid management technology, meeting the ever-evolving demands of modern operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025