Nov . 20, 2024 15:06 Back to list

flanged butterfly valve

Understanding Flanged Butterfly Valves A Key Component in Fluid Control

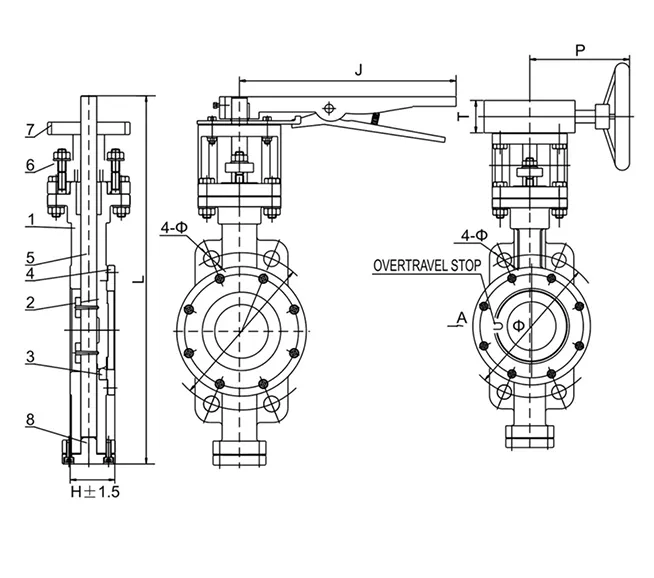

Flanged butterfly valves are pivotal components in various industrial applications, providing effective control over fluid flow in pipelines. These valves are commonly favored for their compact design, reliability, and ease of operation. As an essential instrument in sectors such as water treatment, chemical processing, and HVAC systems, understanding their functionality and benefits is crucial for design engineers and operators alike.

A butterfly valve operates through a rotating disc, which acts as a throttling device to regulate flow. When the valve is fully open, the disc is parallel to the pipe, allowing fluid to pass through with minimal resistance. Conversely, when closed, the disc blocks the flow, effectively sealing the pipeline. The term flanged refers to the valve's connection method. Flanged butterfly valves have protruding flanges on either side, which are designed for bolting the valve securely to the pipeline, ensuring a leak-proof seal.

One significant advantage of flanged butterfly valves is their lightweight design. Unlike other types of valves that can be heavy and cumbersome, butterfly valves are streamlined, making them easier to handle and install. This quality is particularly beneficial in large-scale applications where multiple valves may need to be installed or maintained regularly. Moreover, their design allows for a quick opening and closing mechanism, which is crucial in systems requiring fast operational changes.

flanged butterfly valve

Another important feature of flanged butterfly valves is their versatility. They can be used in various media, including liquids, gases, and slurries. This adaptability makes them suitable for a wide range of applications across different industries. In water treatment facilities, for example, they help regulate the flow of water, ensuring efficient treatment processes. In chemical plants, they control the flow of corrosive substances, highlighting the importance of selecting materials that can withstand chemical exposure.

Flanged butterfly valves also offer cost-effectiveness. They are generally less expensive than other valve types, such as gate or globe valves, both in terms of initial purchase and ongoing maintenance costs. Their simple design means fewer parts that can fail or require replacement, making them a practical choice for budget-conscious operators.

Maintenance of flanged butterfly valves is straightforward. Regular inspection and cleaning are typically sufficient to keep them functioning optimally. Additionally, advancements in technology have led to the development of resilient materials and coatings that enhance durability and performance, reducing downtime and repair costs.

In conclusion, flanged butterfly valves are essential components in fluid control systems, valued for their reliability, lightweight construction, and cost-effectiveness. Their versatility across various industries, coupled with ease of maintenance, underscores their significance in modern engineering applications. As industries continue to evolve, the demand for efficient, effective fluid control solutions will only increase, affirming the role of flanged butterfly valves in future innovations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025