Nov . 17, 2024 08:34 Back to list

Similar Types of Butterfly Valves for Di Lug Applications

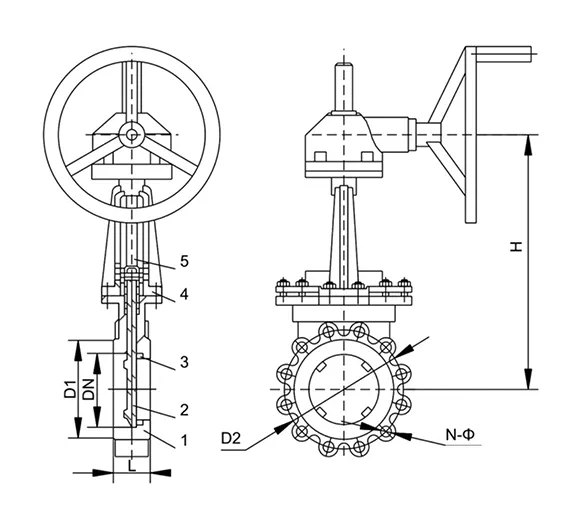

Understanding Di Lug Type Butterfly Valves

Butterfly valves are essential components in various industrial applications, providing efficient flow control and isolation within pipelines. Among the different types of butterfly valves, the double lug type butterfly valve is particularly noteworthy for its design and functionality. This article explores the characteristics, benefits, and applications of di lug type butterfly valves.

Design Features

The di lug type butterfly valve is distinguished by its unique mounting system. It features two lugs attached to the valve body that allow for bolting directly to the flanges in the piping system. This design enables easy installation and removal, making it an attractive option for applications requiring maintenance or replacement. The lugs’ configuration also provides a secure fit, enhancing the valve's reliability and performance under varying pressure conditions.

The body of a di lug butterfly valve is typically constructed from materials such as stainless steel, ductile iron, or PVC, all of which contribute to durability and resistance against corrosion. The disc, which is the pivotal component of the valve, rotates within the flow stream to either throttle or completely shut off the flow. The sealing mechanism often utilizes an elastomeric seat, ensuring minimal leakage and optimal sealing performance.

Advantages

One of the most significant advantages of a di lug type butterfly valve is its compact design. Compared to other valve types, such as gate or globe valves, butterfly valves require less space within the piping system. This makes them an excellent choice for installations with limited space. Additionally, they are lighter, thus reducing the weight on the pipelines and accompanying support structures.

di lug type butterfly valve

Another key benefit is the low operating torque. The design of the butterfly valve allows for smooth rotation of the disc, requiring minimal effort to open and close the valve. This characteristic not only enhances user convenience but also contributes to reducing wear and tear on the valve components.

Moreover, di lug butterfly valves are known for their versatility, as they can be used in various applications, from water and wastewater treatment to HVAC systems and chemical processing. Their ability to handle different media, including gases and liquids, further solidifies their position as a preferred choice among engineers and operators.

Applications

The di lug type butterfly valve finds extensive use across various sectors. In water supply systems, they provide reliable isolation and control over flow, playing a critical role in municipal water management. In the oil and gas industry, these valves facilitate the transport of hydrocarbons, ensuring safety and efficiency.

In HVAC systems, they are often employed to regulate airflow within ductwork, enhancing energy efficiency in heating and cooling applications. Additionally, their use in food and beverage processing ensures sanitary conditions, compliant with industry regulations.

Conclusion

In conclusion, the di lug type butterfly valve is an indispensable tool in modern industry. Its robust design, ease of installation, and versatility across applications make it a valuable asset for flow control and isolation. As industries continue to evolve, the demand for efficient and reliable piping solutions will undoubtedly keep the di lug butterfly valve at the forefront of innovative engineering practices.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025