Dec . 24, 2024 03:22 Back to list

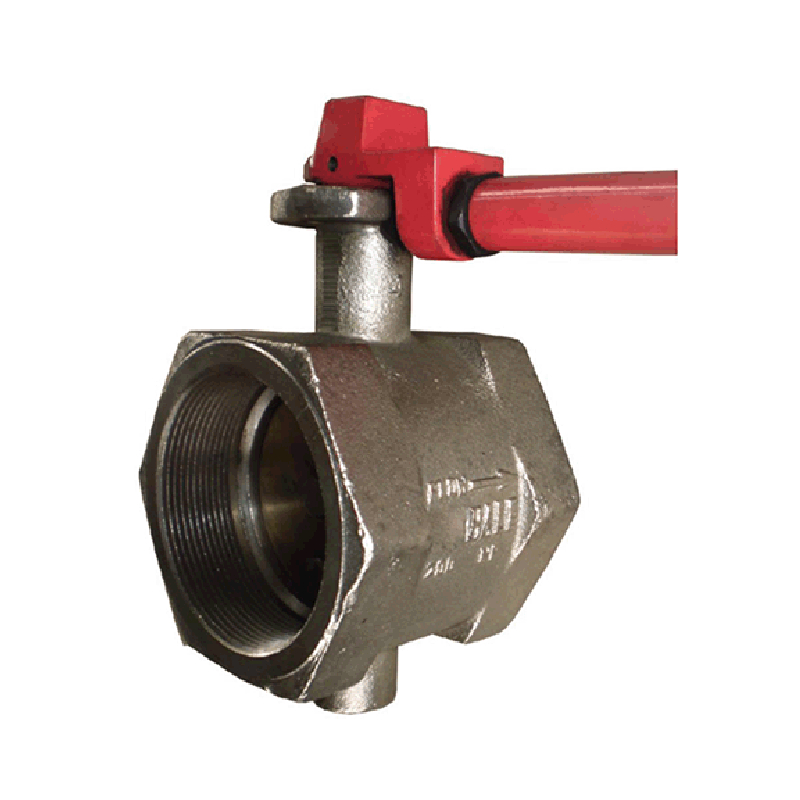

Durable Cast Iron Metal Seat Gate Valve for Reliable Fluid Control Systems

Cast Iron Metal Seat Gate Valve An Overview

Gate valves are essential components in various industrial systems, primarily used for on-off control of fluid flow. Among the various types available, cast iron metal seat gate valves stand out as a robust and reliable choice. Designed for heavy-duty applications, these valves are particularly favored in water supply, sewage treatment, and other fluid management systems due to their advantageous properties and efficient performance.

Material Composition and Structure

Cast iron, an alloy of iron with a high carbon content, is the fundamental material for these valves. Known for its outstanding strength, durability, and resistance to wear, cast iron is well-suited for demanding environments. The choice of metal seats in these gate valves provides a reliable sealing mechanism that minimizes leakage, ensuring effective fluid containment. This is particularly crucial in applications where even minor leaks can lead to significant inefficiencies or environmental risks.

The structure of cast iron gate valves typically includes a body, a gate, and two flanges for connection to pipeline systems. The gate operates through a linear motion; when lifted, it allows fluid to flow freely and, when lowered, stops the flow entirely. This design results in minimal pressure loss through the valve, making it an efficient option for controlling fluid movement.

Advantages of Cast Iron Metal Seat Gate Valves

1. Durability and Longevity One of the most significant benefits of cast iron gate valves is their long life span. The inherent properties of cast iron provide excellent resistance to corrosion and wear, allowing these valves to perform reliably over many years, even in harsh environments.

2. Cost-Effectiveness Cast iron is generally less expensive than other materials such as stainless steel or brass. This affordability, combined with their longevity, makes cast iron metal seat gate valves an economical choice for both initial installation and long-term maintenance.

3. Ease of Maintenance The simple design of gate valves means that they can often be repaired or maintained without the need to dismantle extensive sections of piping. This ease of maintenance can lead to reduced downtime and lower overall operational costs.

cast iron metal seat gate valve

4. Seal Integrity The metal-to-metal seating arrangement in metal seat gate valves provides a reliable seal that is less prone to wear over time compared to other materials, such as rubber or plastic. This minimizes the risk of leakage, contributing to system efficiency and safety.

5. High-Temperature Resistance Cast iron gate valves can typically withstand high-temperature environments, making them suitable for applications involving hot water, steam, or other high-temperature fluids.

Applications

Cast iron metal seat gate valves are widely utilized across multiple industries. In municipal water systems, they play a crucial role in regulating the flow of water and maintaining system pressure. In the wastewater management sector, their durability makes them ideal for handling sewage and effluents without frequent replacements. Furthermore, these valves find applications in industrial processes, such as chemical manufacturing, power generation, and oil and gas production, where reliability and safety are paramount.

Installation and Operation

Proper installation and operation of cast iron gate valves are essential to maximize their benefits. Valves should be installed in the appropriate orientation, ensuring that they are easily accessible for operation and maintenance. During operation, it’s important to fully open or close the valve to avoid unnecessary wear on the gate and sealing surfaces. A partially open gate valve can cause turbulence and increased pressure drop, leading to premature failure.

Conclusion

In summary, cast iron metal seat gate valves are a critical component in numerous fluid management systems, offering durability, cost-effectiveness, and excellent sealing capabilities. Their robustness makes them an ideal choice for a variety of industrial applications, and proper installation and maintenance can further enhance their lifespan and performance. As industries continue to evolve and demand more efficient solutions for fluid control, cast iron gate valves will undoubtedly remain relevant and widely used.

Share