Dec . 26, 2024 17:24 Back to list

air pressure release valve

Understanding Air Pressure Release Valves

Air pressure release valves, commonly referred to as pressure relief valves or safety valves, are critical components utilized in various systems to ensure safe operation and prevent overpressure conditions. These devices act as safeguards, preventing potential hazards that could arise from excessive pressure build-up in pipelines, tanks, and other enclosed systems.

How They Work

The mechanism of an air pressure release valve is relatively straightforward. These valves are designed to open automatically when the pressure inside a system exceeds a pre-set limit. When the pressure rises beyond this threshold, the valve opens and allows excess air, gas, or fluid to escape. This action reduces pressure promptly, preventing damage to the system and minimizing the risk of catastrophic failures.

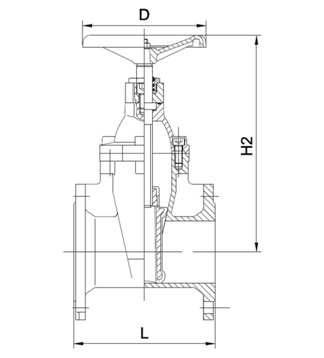

The construction of a typical air pressure relief valve includes a valve body, a seat, a spring, and an actuator. The spring holds the valve closed under normal operating conditions. However, when pressure increases enough to overcome the spring tension, the actuator moves, allowing the valve to open. Once the pressure drops back down to a safe level, the spring forces the valve to close again, restoring normal conditions.

Applications

Air pressure release valves are employed across various industries, including oil and gas, chemical manufacturing, and waste management. In oil refineries, for example, they are vital for controlling pressure in storage tanks where volatile hydrocarbons are housed. In such scenarios, an abrupt pressure increase can lead to explosions or leaks, making pressure relief valves essential for maintaining safety.

In HVAC systems, these valves help regulate air pressure in ducts, preventing issues like duct bursts or inefficient airflow. Additionally, in medical applications, such as in positive pressure ventilators, these valves ensure that the pressure remains within safe thresholds, critical for patient safety.

Importance of Maintenance

air pressure release valve

The effectiveness of an air pressure release valve is contingent upon regular maintenance and testing. Over time, factors such as corrosion, debris accumulation, and mechanical fatigue can impair a valve's functionality. Regular checks are necessary to ensure that the valve opens at the correct pressure and reseals effectively. Routine maintenance can include testing the valve's activation point and ensuring the mechanism is free of obstructions.

Failing to maintain these valves can lead to serious consequences, including equipment failure, environmental disasters, and endangerment of lives. Therefore, industries must adhere to strict maintenance schedules and integrate these checks into their standard operating procedures.

Regulatory Standards

Due to their critical role in safety, air pressure release valves are subject to rigorous regulatory standards established by organizations such as the American Society of Mechanical Engineers (ASME) and the Occupational Safety and Health Administration (OSHA). Compliance with these standards is not only a legal requirement but also a best practice that ensures that the valves function as intended.

Many companies conduct periodic audits to ensure their systems meet these safety standards. They may also implement advanced monitoring technologies, such as pressure sensors and automated control systems, to enhance the oversight of pressure levels and valve functionality.

Future Developments

As technology advances, the design and functionality of air pressure release valves are also evolving. Innovations such as smart valves equipped with sensors and internet connectivity offer real-time data on valve performance and system pressure levels. These developments enable predictive maintenance, allowing operators to address potential issues before they escalate into serious problems.

In summary, air pressure release valves are indispensable features in various systems, serving to protect infrastructure and personnel from the dangers associated with excessive pressure. Their appropriate functioning relies on rigorous maintenance and adherence to safety regulations. As industries continue to innovate, the future of these valves looks promising, paving the way for enhanced safety and efficiency in operation. With ongoing advancements and a strong commitment to safety, we can expect air pressure release valves to remain at the forefront of engineering solutions designed to protect lives and the environment.

Share

-

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025