Dec . 18, 2024 21:33 Back to list

8 inch check valve

Understanding the 8% 20 Inch Check Valve Importance and Applications

In industrial piping systems, the efficiency and reliability of fluid control are paramount. One of the critical components that contribute to this reliability is the check valve. Among various sizes and types of check valves, the 8% 20 inch check valve stands out for its unique capabilities and applications. This article delves into the specifics of this valve, highlighting its design, functionality, and importance in various industries.

What is a Check Valve?

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow in one direction while preventing backflow. This functionality is crucial in systems where backflow could cause pressure fluctuations, damage equipment, or contaminate processes. Check valves are integral to maintaining the integrity of piping systems in applications ranging from wastewater treatment to oil and gas transportation.

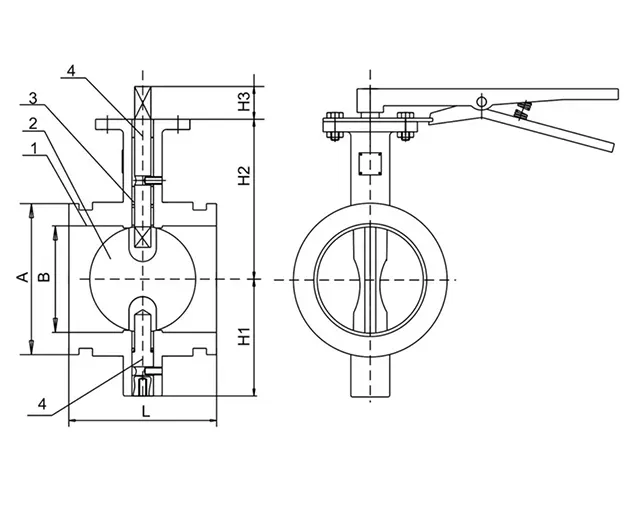

Design and Features of the 8% 20 Inch Check Valve

The designation 8% 20 inch refers to the dimensions and specific characteristics of the valve. The 20 inch measurement indicates the diameter of the valve, making it suitable for large-scale industrial applications. The 8% likely pertains to the valve’s design specification, such as its pressure rating or material density, although specific standards may vary depending on manufacturers and industry requirements.

Key design features of the 8% 20 inch check valve include

1. Material Composition These valves are commonly constructed from durable and corrosion-resistant materials such as stainless steel, brass, or cast iron. The choice of material influences the valve’s longevity and performance, especially in harsh environments.

2. Flow Mechanism Check valves can operate using various mechanisms, such as swing, lift, or ball designs. The specific design determines how quickly and smoothly the valve can open and close in response to pressure changes. An efficient flow mechanism is essential for reducing pressure drops and ensuring smooth operations.

8 inch check valve

3. Size and Weight The 20-inch size indicates a heavy-duty valve capable of managing substantial flow rates. However, the size also requires careful consideration during installation to support its weight and dimensions within the piping system.

Applications of the 8% 20 Inch Check Valve

Due to its robust design and functionality, the 8% 20 inch check valve is utilized across multiple industries

1. Water Supply and Treatment In municipal water supply systems, these valves prevent backflow, protecting water quality and ensuring consistent flow to consumers. They are essential in treatment plants to maintain the orderly flow of water and chemicals.

2. Oil and Gas Industry In pipelines transporting crude oil, natural gas, or refined products, check valves are crucial in preventing reverse flow that could cause leaks or environmental hazards. The size and pressure rating of the 20-inch check valve make it ideal for high-capacity pipelines.

3. Power Generation In thermal or hydroelectric power plants, check valves help manage steam and water flow, ensuring that operations run efficiently and safely. These valves protect pumps and turbines from backflow, which can damage equipment and reduce efficiency.

4. Chemical Processing The chemical industry relies on check valves to prevent fluid backflow that could lead to cross-contamination of chemicals. The ability to select materials resistant to various corrosive substances is vital in this sector.

Conclusion

The 8% 20 inch check valve is a vital component in ensuring the safe and efficient operation of various industrial systems. With its robust design, diverse applications, and ability to prevent backflow, it supports the integrity of pipelines and other fluid handling systems. As industries continue to evolve, the importance of reliable components such as check valves will only increase, underlining the need for ongoing innovation and optimization in valve design and functionality. Investing in high-quality check valves, like the 8% 20 inch model, is crucial for maintaining operational efficiency and safety across many sectors.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025