Jan . 30, 2025 00:41 Back to list

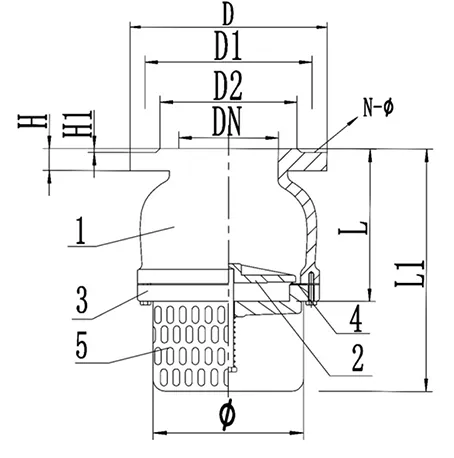

floating ball check valve

When selecting the right valve for various fluid control applications, the floating ball check valve stands as a key innovation, offering a blend of efficiency, reliability, and durability. These valves have gained popularity across numerous industries, from water supply systems to chemical processing, owing to their unique design and operational benefits. They are instrumental in preventing backflow, thus safeguarding the integrity of the piping systems.

Another critical factor contributing to the floating ball check valve's growing dominance is its adaptability in various applications. These valves can handle a broad spectrum of fluids, from viscous oils to gases and slurries, making them a versatile solution for complex fluid handling requirements. The installation of floating ball check valves also speaks to their user-friendly nature. Whether in a new system or replacing an existing valve, the integration process is straightforward, further affirming their cost-effectiveness. Providing ease of installation is essential for industries aiming to optimize operational efficiency, without incurring significant labor costs. Authoritativeness in the market is reinforced through extensive certifications and compliance with international standards. Manufacturers often subject these valves to rigorous testing to ensure they meet industry specifications, guaranteeing superior performance and compliance with safety protocols. This trustworthiness is vital in sectors such as food and beverage or pharmaceuticals, where regulatory compliance and hygiene standards are rigorous. Another dimension adding to their esteem is the extensive support network provided by manufacturers. Offering detailed installation guides, troubleshooting assistance, and readily available spare parts ensures users can rely on a swift resolution of any issues, reinforcing long-term trust in these products. In conclusion, the floating ball check valve embodies a harmonious balance of engineering excellence and practical utility. For industries aiming to enhance fluid handling efficiency while minimizing maintenance requirements and operational costs, investing in these valves presents a strategic move. As they continue to evolve with technological advancements, their role in critical applications highlights their indispensable value in safeguarding fluid system integrity across diverse sectors.

Another critical factor contributing to the floating ball check valve's growing dominance is its adaptability in various applications. These valves can handle a broad spectrum of fluids, from viscous oils to gases and slurries, making them a versatile solution for complex fluid handling requirements. The installation of floating ball check valves also speaks to their user-friendly nature. Whether in a new system or replacing an existing valve, the integration process is straightforward, further affirming their cost-effectiveness. Providing ease of installation is essential for industries aiming to optimize operational efficiency, without incurring significant labor costs. Authoritativeness in the market is reinforced through extensive certifications and compliance with international standards. Manufacturers often subject these valves to rigorous testing to ensure they meet industry specifications, guaranteeing superior performance and compliance with safety protocols. This trustworthiness is vital in sectors such as food and beverage or pharmaceuticals, where regulatory compliance and hygiene standards are rigorous. Another dimension adding to their esteem is the extensive support network provided by manufacturers. Offering detailed installation guides, troubleshooting assistance, and readily available spare parts ensures users can rely on a swift resolution of any issues, reinforcing long-term trust in these products. In conclusion, the floating ball check valve embodies a harmonious balance of engineering excellence and practical utility. For industries aiming to enhance fluid handling efficiency while minimizing maintenance requirements and operational costs, investing in these valves presents a strategic move. As they continue to evolve with technological advancements, their role in critical applications highlights their indispensable value in safeguarding fluid system integrity across diverse sectors.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025