Nov . 14, 2024 14:20 Back to list

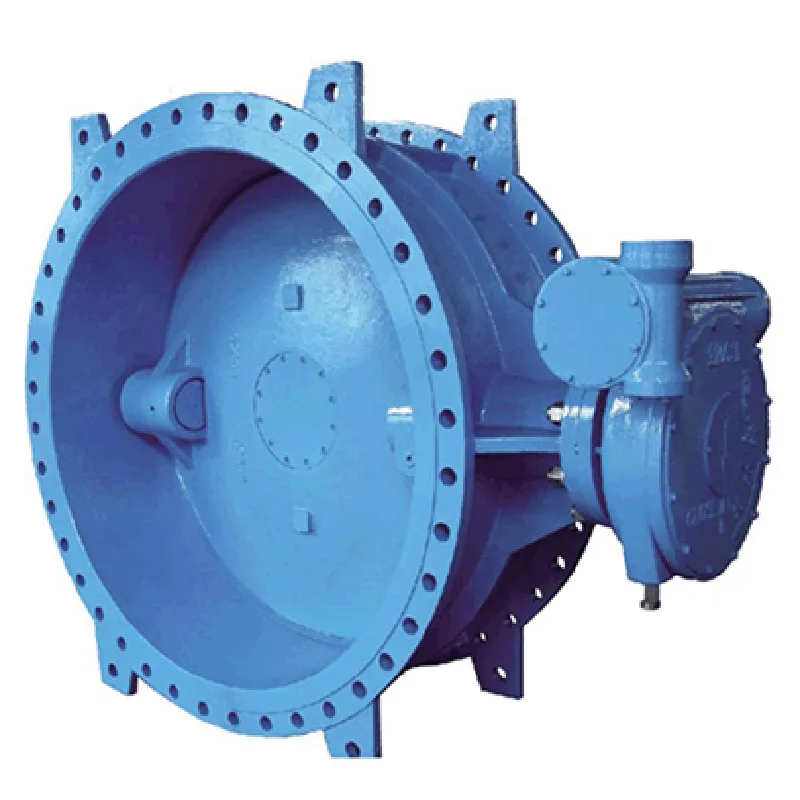

electric gate valve actuators

The Importance of Electric Gate Valve Actuators in Modern Industries

In the realm of industrial automation, the significance of precise control over fluid movement cannot be overstated. Electric gate valve actuators have emerged as an essential component in a wide range of industries, contributing to the efficiency, safety, and reliability of operations. These devices play a crucial role in regulating the flow of liquids and gases, making them indispensable in various applications, from water treatment plants to petrochemical facilities.

Understanding Electric Gate Valve Actuators

Electric gate valve actuators are devices that open and close gate valves using electrical energy. Unlike manual actuators, which require physical force for operation, electric actuators offer improved accuracy and speed. They consist of an electric motor coupled with a gear mechanism that converts rotational motion into linear motion, effectively controlling the valve's position.

These actuators can be divided into two main categories on-off actuators and modulating actuators. On-off actuators are designed to fully open or close a valve, while modulating actuators can adjust the valve's position gradually to control the flow rate, providing more versatility for applications requiring precise flow regulation.

Advantages of Using Electric Gate Valve Actuators

1. Precision and Control Electric actuators deliver superior precision in valve positioning compared to their manual counterparts. This is crucial in processes where maintaining an exact flow rate is vital to operational efficiency and product quality.

2. Automation and Integration The ability to integrate electric gate valve actuators into automated systems enhances overall process efficiency. These actuators can be controlled remotely via a centralized control system, allowing for real-time monitoring and adjustments.

3. Reduced Labor Costs By minimizing the need for manual operation, electric actuators significantly reduce labor costs. Operators can manage multiple valves from a distance, enabling better resource allocation and reducing the risk of human error.

4. Safety and Reliability With built-in features such as position feedback and fail-safe options, electric gate valve actuators enhance safety in the workplace. In applications involving hazardous materials, having reliable actuators that can respond quickly to control commands is vital for preventing accidents.

5. Energy Efficiency Modern electric actuators are designed with energy efficiency in mind. They typically consume less power than traditional pneumatic or hydraulic actuators, leading to lower operational costs and reduced environmental impact.

electric gate valve actuators

Applications of Electric Gate Valve Actuators

Electric gate valve actuators are employed across various sectors

- Water and Wastewater Treatment They control the flow of water and chemicals in treatment plants to ensure efficient processing and compliance with environmental regulations.

- Oil and Gas Industry These actuators manage the flow of crude oil, natural gas, and refined products, ensuring safe and efficient operation in pipelines, refineries, and distribution systems.

- Chemical Processing In chemical plants, precise flow control is critical. Electric actuators aid in the safe handling of reactive and hazardous substances.

- Power Generation Electric actuators regulate cooling water and steam flow in power plants, helping to optimize plant performance and efficiency.

- Food and Beverage Industry These actuators help maintain the needed levels of sanitary and controlled processing conditions, contributing to product quality and safety compliance.

Conclusion

In conclusion, electric gate valve actuators are vital components that enhance the operation of various industrial processes. Their precision, efficiency, and integration capabilities position them as a preferred choice over manual and traditional actuators. As industries continue to evolve towards more automated and efficient operations, the role of electric gate valve actuators will undoubtedly become more prominent.

Organizations looking to improve their operational efficiency, enhance safety, and reduce costs would do well to consider the benefits that electric gate valve actuators provide. With ongoing advancements in technology, these actuators are likely to become even more sophisticated, further driving innovation in industrial automation. Whether in water treatment, oil and gas, or chemical processing, electric gate valve actuators are paving the way for a more efficient and reliable future.

Share