Feb . 19, 2025 08:15 Back to list

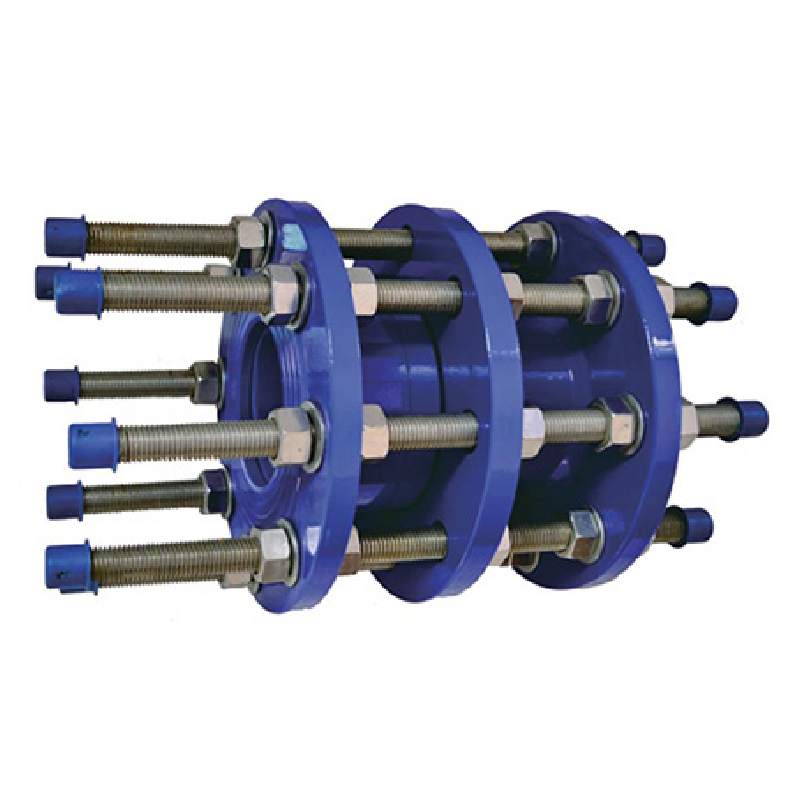

flange type butterfly valve

The wafer type butterfly valve flange is an essential component in fluid control systems, enabling precise regulation of fluid flow in various industrial applications. As a seasoned expert in the field of fluid mechanics and industrial valve technology, I've seen firsthand how the quality and design of these components can significantly impact system performance.

Another important aspect to consider is the sealing mechanism. Wafer type butterfly valves typically employ either a soft or metal seat seal. Soft seats, often made from elastomeric materials like EPDM or NBR, offer superior sealing for low-pressure applications. However, for high-temperature environments, a metal seat may be more appropriate, providing a durable and reliable seal without degradation over time. The precision engineering involved in manufacturing these components lends itself to robust performance characteristics. Manufacturers often employ advanced machining technologies to ensure the utmost precision in construction, resulting in excellent flow control capabilities. The interplay of disk alignment and seat integrity is critical, and any imperfections can lead to inefficient operation or leakages, underscoring the importance of selecting a high-quality manufacturer. In terms of compliance and standards, wafer type butterfly valve flanges must adhere to stringent specifications such as API, ISO, and ASME, ensuring they meet global safety and performance benchmarks. Buyers should always verify the certifications and testing protocols that a product has undergone before installation. This diligence ensures not just operational efficiency but also the safety and reliability of the entire system. Lastly, it’s crucial to collaborate with knowledgeable suppliers or manufacturers who can provide not only the product but also insight into its optimal use and installation. This partnership can illuminate potential issues before they arise and offer innovative solutions tailored to specific operational demands. To sum up, the wafer type butterfly valve flange is a versatile, efficient, and cost-effective solution in fluid control systems, offering reliable performance across a spectrum of industrial applications. Its design, material choice, and compliance with international standards underscore its value as a critical component in modern engineering systems. Customers investing in these flanges benefit from the flexibility, efficiency, and reliability that they provide, which are crucial factors in maintaining system integrity and maximizing operational uptime.

Another important aspect to consider is the sealing mechanism. Wafer type butterfly valves typically employ either a soft or metal seat seal. Soft seats, often made from elastomeric materials like EPDM or NBR, offer superior sealing for low-pressure applications. However, for high-temperature environments, a metal seat may be more appropriate, providing a durable and reliable seal without degradation over time. The precision engineering involved in manufacturing these components lends itself to robust performance characteristics. Manufacturers often employ advanced machining technologies to ensure the utmost precision in construction, resulting in excellent flow control capabilities. The interplay of disk alignment and seat integrity is critical, and any imperfections can lead to inefficient operation or leakages, underscoring the importance of selecting a high-quality manufacturer. In terms of compliance and standards, wafer type butterfly valve flanges must adhere to stringent specifications such as API, ISO, and ASME, ensuring they meet global safety and performance benchmarks. Buyers should always verify the certifications and testing protocols that a product has undergone before installation. This diligence ensures not just operational efficiency but also the safety and reliability of the entire system. Lastly, it’s crucial to collaborate with knowledgeable suppliers or manufacturers who can provide not only the product but also insight into its optimal use and installation. This partnership can illuminate potential issues before they arise and offer innovative solutions tailored to specific operational demands. To sum up, the wafer type butterfly valve flange is a versatile, efficient, and cost-effective solution in fluid control systems, offering reliable performance across a spectrum of industrial applications. Its design, material choice, and compliance with international standards underscore its value as a critical component in modern engineering systems. Customers investing in these flanges benefit from the flexibility, efficiency, and reliability that they provide, which are crucial factors in maintaining system integrity and maximizing operational uptime.

Share

Prev:

Latest news

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025