Dec . 15, 2024 15:46 Back to list

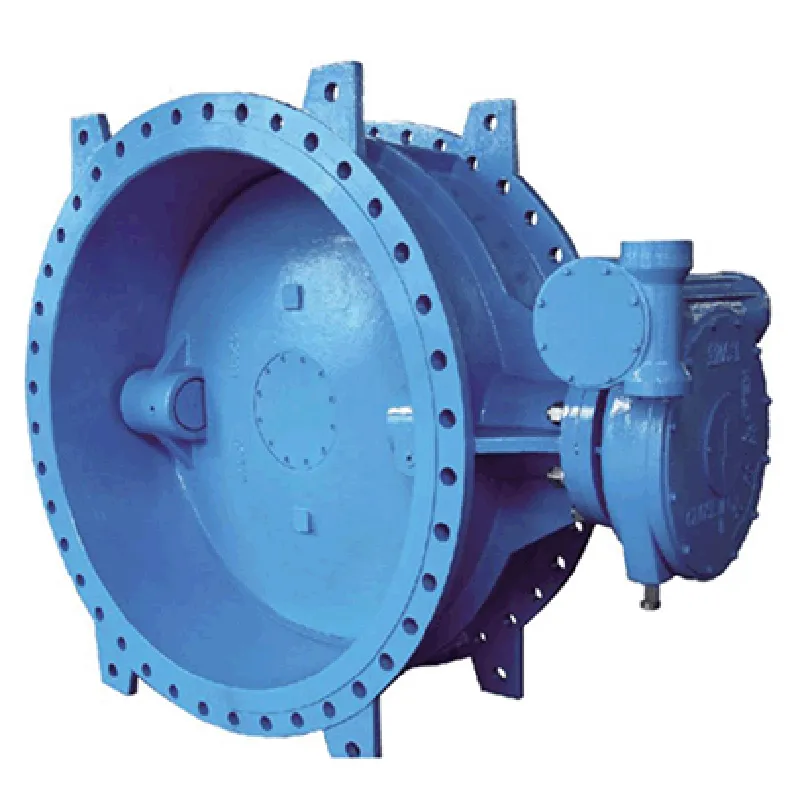

wafer and lugged butterfly valve

Wafer and Lugged Butterfly Valves A Comparative Overview

Butterfly valves are widely utilized in various industrial applications due to their efficient flow control, compact design, and cost-effectiveness. Among the popular designs, wafer and lugged butterfly valves stand out, each featuring unique characteristics that render them suitable for specific environments.

What Are Butterfly Valves?

Butterfly valves are quarter-turn rotational valves used to regulate fluid flow. They consist of a disc, which rotates around a central axis, allowing or blocking the flow of fluids when turned. The design is simple yet effective, which is why they are commonly found in water treatment plants, oil and gas pipelines, and HVAC systems.

Wafer Butterfly Valves

Wafer butterfly valves are characterized by their slim profile and are designed to fit between two flanges in a pipeline. They do not use any additional flanged fittings for mounting, which significantly reduces installation space. Wafer valves typically have a centrally located disc that can be opened or closed by a lever or actuator.

One of the main advantages of wafer butterfly valves is their lightweight nature, making them easier to handle and install. The compact design facilitates easier integration into tight spaces within piping assemblies. Moreover, they are generally more cost-effective compared to lugged versions, making them a popular choice for projects with budget constraints.

However, wafer butterfly valves have some limitations. Since they depend on the flanges for mounting, they may not be as suitable for systems that require frequent disassembly or maintenance. Additionally, the gasket used in wafer designs must be compatible with the medium being transported to prevent leakage.

Lugged Butterfly Valves

wafer and lugged butterfly valve

In contrast, lugged butterfly valves feature lugs or threaded holes on their body, allowing direct mounting to the pipe without additional flanges. This makes them more versatile for different piping configurations and easier to install in situations requiring isolation or maintenance.

The design of lugged butterfly valves permits the valve to be removed without causing any disruptions to the pipeline or the flow of the fluid. This feature allows for a more straightforward replacement process and contributes to the overall efficiency of valve maintenance. Lugged butterfly valves are particularly advantageous in critical applications, such as in chemical processing or in systems where shut-off capabilities are essential.

Nonetheless, lugged butterfly valves tend to be heavier and bulkier than wafer types, potentially requiring more effort during installation. They also generally come at a higher cost, which can be a significant consideration for large projects.

Applications and Considerations

When deciding between wafer and lugged butterfly valves, several factors should be taken into account, including the nature of the application, installation constraints, maintenance requirements, and budget. Wafer valves are often preferred in simple, space-constrained applications where cost is a primary concern. In contrast, lugged butterfly valves are ideal for systems requiring regular maintenance and accessibility.

Both valve types can be made from a variety of materials, including stainless steel, cast iron, and plastic, allowing for compatibility with different media, whether corrosive, abrasive, or non-corrosive.

Conclusion

In summary, wafer and lugged butterfly valves both play crucial roles in fluid control systems. Understanding their distinct properties and best-use scenarios is essential for engineers and project managers to make informed decisions. By carefully evaluating the specific requirements of an application, one can optimize performance while maintaining cost efficiency in valve selection.

Share