Nov . 12, 2024 05:44 Back to list

trunnion mounted

Understanding Trunnion Mounted Devices

Trunnion mounted systems are pivotal components in various industrial applications, particularly in the fields of mechanical engineering, manufacturing, and construction. At its core, the term trunnion refers to a cylindrical protrusion used as a mounting or pivoting point on which an object may rotate or swing. This design is essential in applications where stable support and rotation are required, offering both strength and versatility.

The Design and Function of Trunnion Mounted Systems

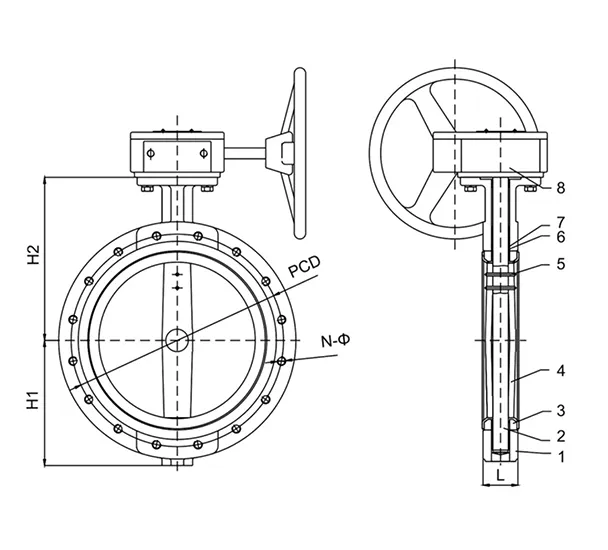

Trunnion mounted devices typically consist of a cylindrical shaft that is anchored to a base or frame, allowing the attached mechanism to pivot around the shaft. This pivoting capability is crucial in numerous applications, such as in valves, cranes, and various heavy machinery, where movement in multiple directions is needed.

One of the most common applications of trunnion mounted systems is in the valve industry. Trunnion mounted ball valves provide low friction and easy operation, making them ideal for controlling the flow of liquids and gases in pipelines. Their robust design minimizes wear and tear, extending the lifespan of the valve. Unlike floating ball valves that depend on the pressure of the fluid to keep the ball in place, trunnion mounted ball valves anchor the ball securely in position, making them ideal for high-pressure applications.

Advantages of Trunnion Mounted Systems

The design of trunnion mounted systems comes with several distinct advantages

1. Stability Trunnion mounting provides a stable base for the pivoting mechanism. This stability is particularly important in applications where load distribution is critical, reducing wear on components and extending overall equipment life.

2. Reduced Friction The pivot design reduces friction between moving parts, allowing for smoother operation. This reduction in friction translates into lower energy consumption and improved efficiency for machines that rely on these systems.

3. High Load Capacity Trunnion mounted systems can handle significant loads, making them suitable for heavy-duty applications. They can support large valves or equipment without compromising performance.

trunnion mounted

4. Versatile Orientation The pivoting action allows for versatile orientation in operation. This feature is beneficial in applications such as cranes, where the load needs to be moved in multiple directions.

5. Ease of Maintenance Trunnion mounted devices are often designed with accessibility in mind, making maintenance and replacement of parts more straightforward compared to other designs.

Applications Across Industries

Trunnion mounted systems are widespread across various sectors. In the oil and gas industry, for instance, trunnion mounted ball valves are crucial for the safe and efficient control of fluid flow in pipelines. Any failure in these systems can lead to significant issues, including leaks and operational inefficiencies.

In construction and heavy machinery, cranes with trunnion mounting allow for precise movement and control of heavy loads. This capability is vital for construction projects, where safety and precision are paramount. Additionally, manufacturers utilize trunnion mounted devices in conveyor systems, where consistent and reliable movement of materials is necessary.

Recent Innovations

As industries evolve, so do the technologies surrounding trunnion mounted systems. Innovations in materials science have led to the development of stronger and lighter materials, which can enhance the performance and efficiency of trunnion mounted devices. Additionally, advancements in automation and smart technology are beginning to integrate into these systems, allowing for real-time monitoring and control that enhances operational efficiency and safety.

Conclusion

Trunnion mounted systems represent an important innovation in mechanical design, providing reliable, efficient, and versatile solutions for a multitude of industrial applications. Their stability, load capacity, and ease of maintenance make them indispensable in fields such as oil and gas, construction, and manufacturing. As technology continues to advance, it is likely that the trunnion mounted design will adapt and integrate new innovations, further solidifying its role in modern engineering and industrial practices. Understanding the value and function of these systems is vital for engineers and technicians as they design, implement, and maintain the machinery that drives our industries forward.

Share