Jan . 15, 2025 03:24 Back to list

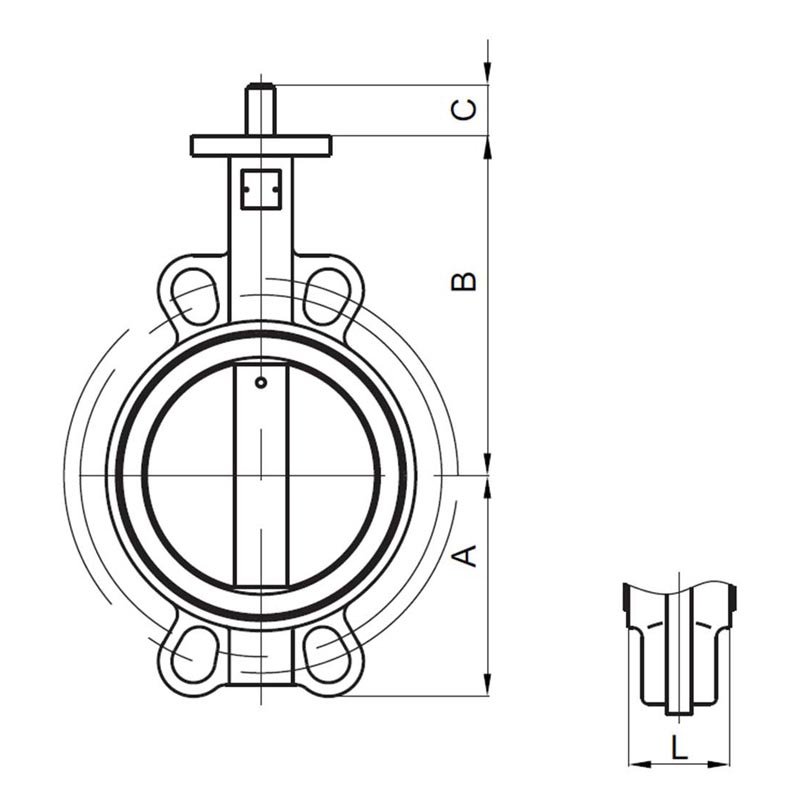

ci wafer type check valve

Silent wafer check valves stand out as pivotal components in fluid control systems, designed to prevent the backflow of liquids or gases while minimizing noise and vibration. Their compact, streamlined construction is what sets them apart from more traditional check valves, making them an ideal choice for applications where space is constrained.

When it comes to authoritativeness, manufacturers of silent wafer check valves often provide detailed specifications and testing certifications that validate performance under various conditions. Leading companies in the industry often comply with international standards such as ISO or API, offering assurance of quality and reliability. Reviewing these certifications can be a decisive factor in selecting the right valve for a given application. Trustworthiness is largely built on the reputation of both the product and the supplier. Experienced users often share insights through reviews or case studies, detailing the valve's performance over time in specific environments. Trust is further reinforced by warranties offered by manufacturers, which serve as a testament to the product's durability and the company's confidence in its offering. In conclusion, silent wafer check valves are indispensable for systems requiring reliable backflow prevention with minimal noise. Their design and material variety cater to a wide range of applications, from industrial to commercial uses. Professionals choosing these valves benefit from understanding technical specifications and installation guidelines, ensuring optimal performance and a longer lifecycle. As silent wafer check valves continue to evolve, they remain a testament to engineering ingenuity, representing a balance between form, function, and innovation in modern fluid control systems.

When it comes to authoritativeness, manufacturers of silent wafer check valves often provide detailed specifications and testing certifications that validate performance under various conditions. Leading companies in the industry often comply with international standards such as ISO or API, offering assurance of quality and reliability. Reviewing these certifications can be a decisive factor in selecting the right valve for a given application. Trustworthiness is largely built on the reputation of both the product and the supplier. Experienced users often share insights through reviews or case studies, detailing the valve's performance over time in specific environments. Trust is further reinforced by warranties offered by manufacturers, which serve as a testament to the product's durability and the company's confidence in its offering. In conclusion, silent wafer check valves are indispensable for systems requiring reliable backflow prevention with minimal noise. Their design and material variety cater to a wide range of applications, from industrial to commercial uses. Professionals choosing these valves benefit from understanding technical specifications and installation guidelines, ensuring optimal performance and a longer lifecycle. As silent wafer check valves continue to evolve, they remain a testament to engineering ingenuity, representing a balance between form, function, and innovation in modern fluid control systems.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025