Dec . 12, 2024 12:06 Back to list

Flange Dismantling Joint Installation and Maintenance Guide for Efficient Pipeline Solutions

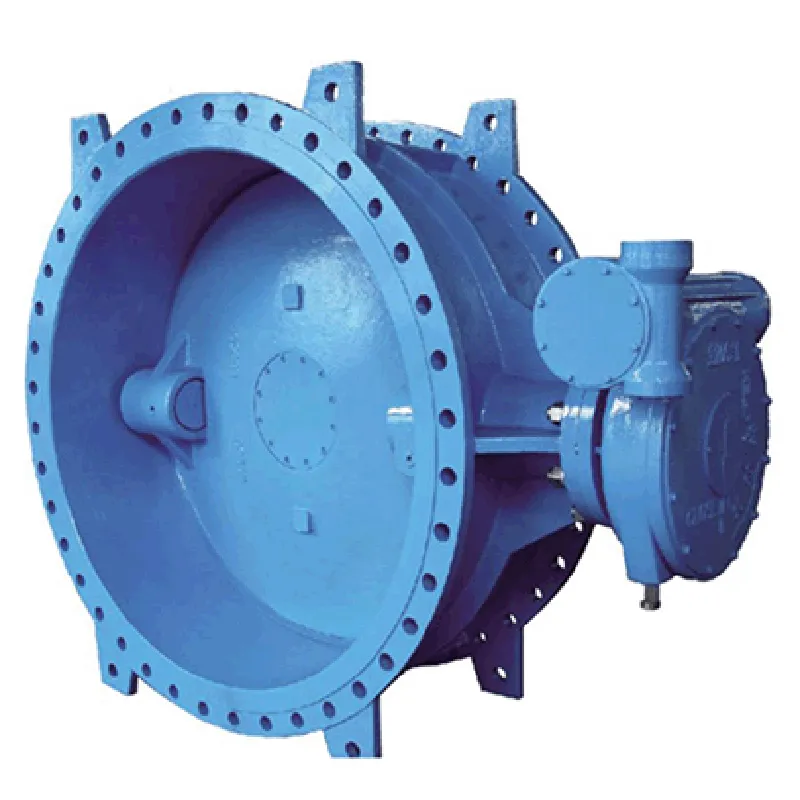

Understanding the Flange Dismantling Joint A Comprehensive Guide

In various industrial applications, the flange dismantling joint plays a crucial role in ensuring efficient maintenance and seamless operations of piping systems. This specialized component allows for the disconnection and reconnection of pipes without the need for removing the entire assembly, simplifying installation, maintenance, and repairs. In this article, we will explore the features, benefits, and applications of flange dismantling joints, as well as considerations for their installation and maintenance.

What is a Flange Dismantling Joint?

A flange dismantling joint, often referred to simply as a dismantling joint, is a mechanical device used to connect two lengths of pipe while allowing for axial movement. These joints are characterized by their flanged design, which facilitates easy attachment to existing piping systems. Typically crafted from robust materials such as carbon steel or stainless steel, dismantling joints are engineered to withstand varying pressures and temperatures, making them suitable for diverse industrial environments.

Key Features and Benefits

1. Ease of Installation and Maintenance One of the primary advantages of flange dismantling joints is the ease with which they can be installed and maintained. When repairs are necessary, technicians can easily dismantle the joint, access the internal components of the piping system, and perform maintenance without cutting or welding. This reduces downtime and overall costs associated with plumbing repairs.

2. Adjustment Capabilities Flange dismantling joints provide a degree of flexibility in terms of alignment adjustment. They often come equipped with a telescopic design, enabling users to fine-tune the position of the pipelines during installation. This feature is particularly beneficial in situations where precise alignment is critical for optimal system performance.

3. Durability and Reliability Built to withstand the rigors of industrial use, flange dismantling joints are manufactured with high-quality materials that resist corrosion and mechanical wear. Their robust construction ensures a long service life, reducing the frequency of replacements and associated costs.

4. Versatility These joints can be utilized in various applications, including water supply systems, sewage treatment plants, oil and gas pipelines, and heating systems. Their adaptability makes them invaluable across multiple sectors, from municipal to industrial.

flange dismantling joint

5. Pressure and Temperature Resistance Flange dismantling joints are designed to accommodate different pressure ratings and temperature ranges, making them suitable for diverse operational conditions. This adaptability is essential for ensuring safety and functionality in various environments.

Installation Considerations

While flange dismantling joints offer substantial advantages, proper installation is critical to ensure their effectiveness. Here are some considerations to keep in mind

1. Alignment It is vital to ensure that the joint is correctly aligned with the adjoining pipes to prevent undue stress on the connection, which could lead to failures or leaks.

2. Gasket Selection The choice of gasket material should be suitable for the media being transported, as different materials offer varying levels of resistance to chemicals, temperatures, and pressures.

3. Torque Requirements Adhering to the manufacturer’s specifications regarding bolt torque is essential for achieving a secure connection. Over-tightening or under-tightening can compromise the integrity of the joint.

4. Regular Maintenance Although dismantling joints simplify repairs, regular inspections should be performed to check for signs of wear or damage. Routine maintenance can prevent unexpected failures and extend the service life of the piping system.

Conclusion

In summary, flange dismantling joints are pivotal components in modern piping systems, offering ease of maintenance, alignment adjustments, and durability. Their versatility across various industrial applications underscores their importance in ensuring efficient operations and minimizing downtime. By adhering to proper installation and maintenance practices, users can maximize the performance and longevity of these invaluable systems. As industries continue to evolve and seek more efficient solutions, the flange dismantling joint will undoubtedly remain a trusted component in the engineering toolkit.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025