Nov . 10, 2024 18:20 Back to list

Automated Butterfly Valve Solutions for Efficient Fluid Control Systems and Applications

Understanding Butterfly Valves with Actuators

Butterfly valves are essential components in various industrial applications, primarily used for regulating and isolating the flow of fluids. These valves possess a simple yet effective design, characterized by a rotating disc that is mounted on a shaft. The actuator, an additional device, plays a critical role in automating the operation of the butterfly valve, making it an integral part of modern fluid control systems.

The Structure of Butterfly Valves

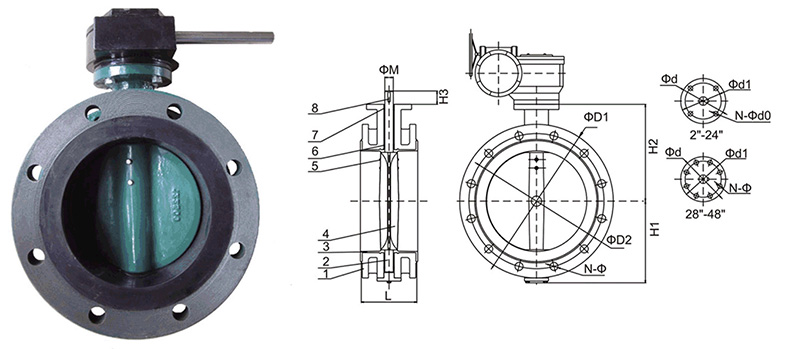

A typical butterfly valve consists of three main components the body, the disc, and the actuator. The body is the outer casing of the valve, designed to be mounted inline in a piping system. The disc, which resembles a butterfly wing, pivots on a shaft to control fluid flow—when the disc is parallel to the flow, it is open; when perpendicular, it is closed. This rotating action allows for quick and efficient flow control, making butterfly valves preferable in many applications.

The Role of Actuators

An actuator is a device that provides the necessary force to operate the valve. Butterfly valves can be operated manually via a handwheel, or they can be automated using electric, pneumatic, or hydraulic actuators. Automated actuators enhance the efficiency of fluid control by enabling remote operation, precise control, and quick response times.

1. Electric Actuators These are the most common type of actuators used with butterfly valves. They convert electrical energy into mechanical energy, allowing for precise positioning of the valve. Electric actuators are known for their accuracy and ability to provide real-time feedback to control systems. They are ideal for applications where the valve must be adjusted frequently or require integration into automated systems.

2. Pneumatic Actuators These use compressed air to actuate the valve. Pneumatic actuators are favored in environments where rapid valve operation is necessary, such as in chemical processing and water treatment facilities. They can open and close valves faster than electric actuators, making them suitable for high-speed applications.

3. Hydraulic Actuators Similar to pneumatic actuators, hydraulic actuators use fluid pressure to generate movement. These are typically employed in heavy-duty applications where significant torque and force are required. Hydraulic actuators can handle larger butterfly valves, particularly in oil and gas industries, where pressures can be extremely high.

butterfly valve with actuator

Advantages of Butterfly Valves with Actuators

The combination of butterfly valves and actuators offers several significant advantages that enhance operational efficiency and reliability

- Space Efficiency Butterfly valves are compact and lightweight compared to other valve types, making them suitable for installations where space is limited. Automated actuators do not significantly increase the footprint of the valve system.

- Flow Control Butterfly valves provide excellent flow control capabilities. With actuators, precise positioning of the valve can be achieved, allowing for optimal flow regulation. This is particularly crucial in processes that require specific flow rates, such as in power generation or water distribution systems.

- Reduced Maintenance Automated butterfly valves typically require less maintenance compared to manual valves. The wear and tear associated with frequent manual adjustments is minimized, as actuator technology often includes features like limit switches and feedback systems that help maintain optimal performance.

- Versatility Butterfly valves with actuators can be used in various applications across different industries, including water treatment, oil and gas, food processing, and HVAC systems. They can handle a range of fluids—liquid or gas—and are effective in both low and high-pressure environments.

Conclusion

Butterfly valves paired with actuators represent a culmination of innovation in fluid control technology. Their simplicity, combined with the precision offered by actuators, makes them indispensable in many industrial settings. As industries continue embracing automation and smart technologies, the demand for butterfly valves with actuators will likely grow. Understanding their operation and benefits is crucial for engineers and technicians working to optimize fluid management systems. Whether used in manufacturing, energy production, or environmental applications, these valves promise reliability and efficiency, ensuring smooth operational flow in various processes.

Share