Sep . 29, 2024 00:47 Back to list

Flanged Swing Check Valve for Optimal Flow Regulation and Backflow Prevention Solutions

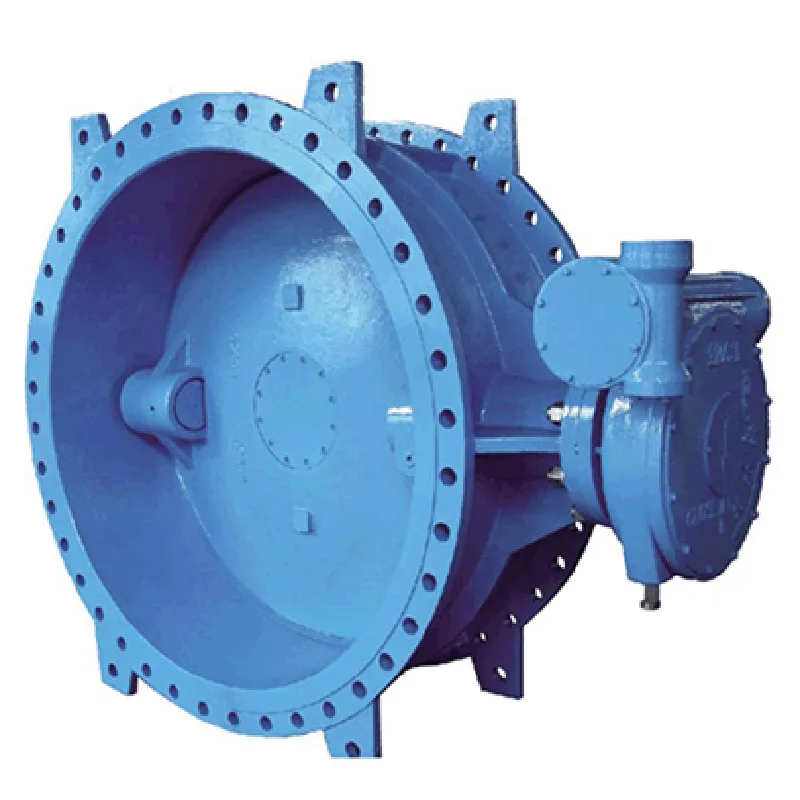

Understanding Flanged Swing Check Valves Design, Functionality, and Applications

Flanged swing check valves are an essential component in various piping systems, designed to allow fluid to flow in one direction while preventing backflow. This type of valve is particularly popular in industrial applications due to its reliability, durability, and efficient performance. In this article, we will explore the design, functionality, and applications of flanged swing check valves, as well as the advantages they offer in fluid management.

Design Features

Flanged swing check valves consist of a valve body, a swing disc, and a hinge pin. The valve body is equipped with flanged ends, making it easy to connect to other piping systems. These flanges conform to various standards such as ASME, ANSI, or DIN, allowing for compatibility with different piping configurations.

The swing disc is mounted on a hinge pin and opens and closes against the flow of fluid. When fluid flows in the designated direction, the disc swings open, allowing for unimpeded flow. Conversely, when the fluid attempts to flow back, the disc swings closed, sealing off the valve and preventing reverse flow. Flanged swing check valves can be made from a variety of materials, including cast iron, stainless steel, and brass, to suit different environmental and pressure conditions.

Functionality

The primary function of a flanged swing check valve is to prevent backflow in a piping system. This is crucial in preventing potential contamination of fluids, protecting equipment, and ensuring safe operation within industrial processes. The design of the swing disc allows for minimal pressure drop across the valve, which is a significant advantage over other types of check valves, such as ball check valves.

Additionally, flanged swing check valves operate smoothly under varying flow conditions. Their simple mechanical design reduces the risk of failure due to wear and tear, offering a dependable solution for managing fluid dynamics. It is important to note that these valves are best suited for horizontal and vertical installations, where the flow direction can be clearly defined.

flanged swing check valve

Applications

Flanged swing check valves are widely used across various industries, including water treatment, oil and gas, power generation, and HVAC systems. In water treatment plants, they help manage the flow of water and wastewater while preventing backflow that could lead to cross-contamination. In the oil and gas industry, these valves are crucial for maintaining pipeline integrity, ensuring that crude oil, natural gas, and other fluids flow safely through vast networks of pipes.

The power generation sector also relies on flanged swing check valves for controlling steam and water flows in power plants. Their ability to operate effectively in high-pressure applications makes them suitable for use in boilers and turbines. Furthermore, HVAC systems utilize these valves to maintain proper airflow and prevent the backflow of refrigerants, contributing to the efficiency of heating and cooling processes.

Advantages

One of the primary advantages of flanged swing check valves is their low maintenance requirement. Their robust design reduces the likelihood of leaks and failures, making them a cost-effective solution over time. Additionally, the minimal pressure loss across the valve translates to energy savings, which is particularly important in large-scale industrial applications.

Furthermore, flanged swing check valves are relatively easy to install and can be integrated seamlessly into existing systems. Their compatibility with various piping standards ensures that they can be used in a wide range of applications without the need for extensive modifications.

Conclusion

Flanged swing check valves play a vital role in maintaining the efficiency and safety of fluid transport systems across various industries. Their simple yet effective design, combined with their reliability and versatility, makes them a preferred choice for engineers and operators alike. Understanding the features and functionalities of these valves can help ensure proper selection and installation, ultimately enhancing the performance of any piping system. Whether it be for water treatment, oil and gas, power generation, or HVAC applications, flanged swing check valves continue to be an integral part of modern industrial infrastructure.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025