Dec . 05, 2024 07:11 Back to list

Wafer Style Dual Disc Check Valve for Efficient Flow Control

Understanding the Dual Plate Check Valve (Wafer Type)

The dual plate check valve, often referred to as a wafer type valve, represents a critical component in various fluid management systems across several industries, including water treatment, oil and gas, and chemical processing. This valve type is designed to prevent backflow in piping systems, ensuring that fluids flow in one direction only. Its unique construction and operational features make it particularly advantageous for certain applications.

Design and Structure

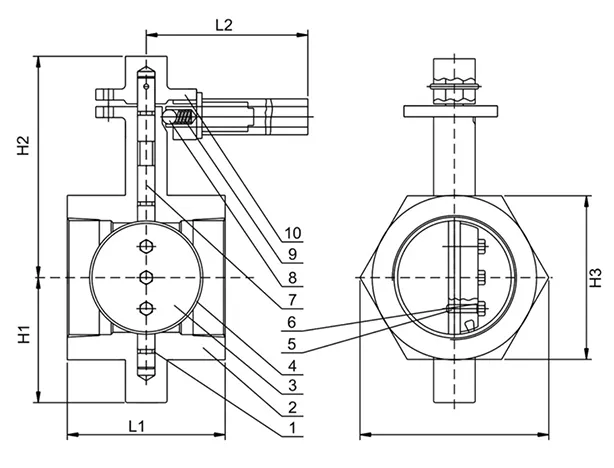

The dual plate check valve consists of two disc-like plates that pivot around a central pivot point. These plates open as fluid flows through the valve, allowing it to pass through, and close when the flow reverses, thereby preventing backflow. The wafer type design is characterized by its compactness and lightweight construction, making it easier to install between flanges in a pipeline, unlike traditional flanged check valves that require more space.

One of the significant benefits of the dual plate check valve is its ability to maintain a low profile within the pipeline, which reduces the overall weight and installation footprint. This design also minimizes the pressure drop across the valve, making it an energy-efficient choice for systems requiring smooth fluid flow with reduced turbulence.

Material and Performance Attributes

Dual plate check valves can be constructed from various materials, including stainless steel, cast iron, and bronze, depending on the specific application and fluid being controlled

. The choice of material impacts not only the valve's durability and resistance to corrosion but also its performance in high-pressure and high-temperature environments.The performance of these valves can be significantly improved with the addition of features such as soft seating, which ensures a tighter seal and reduces the likelihood of leakage. Moreover, the design minimizes slamming—a common issue in check valves that can lead to increased wear and tear, noise, and eventually, failure. As the plates open and close quickly in response to changing flow conditions, the dual plate check valves provide a smoother operation compared to their conventional counterparts.

dual plate check valve wafer type

Applications

The versatility of dual plate check valves makes them suitable for a wide array of applications. In water treatment facilities, they are employed to prevent backflow that could contaminate clean water supplies. In the oil and gas industry, these valves are critical for ensuring the safe and efficient transport of hydrocarbons, where backflow could pose severe operational risks.

Additionally, in HVAC systems, dual plate check valves play a role in maintaining system pressure and ensuring that heated or cooled air flows in the desired direction. Their reliability and efficiency make them an essential part of any fluid control strategy.

Installation and Maintenance

Installing a dual plate check valve is generally straightforward, but it is essential to ensure that it is oriented correctly within the pipeline. Incorrect installation can lead to performance issues, including failure to prevent backflow. Regular maintenance is also vital to ensure that the valve operates effectively over time. Inspections should include checking for wear on the disc plates, ensuring that the hinges and seals are in good condition, and verifying that there are no obstructions preventing the valve from closing properly.

Conclusion

In conclusion, dual plate check valves (wafer type) are indispensable components in various fluid control systems. Their innovative design, combined with material versatility and performance efficiency, makes them ideal for preventing backflow and enhancing overall system integrity. Understanding how to effectively utilize and maintain these valves is crucial for any professional working within industries that rely on reliable fluid management solutions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025