okt . 31, 2024 20:16 Back to list

Wafer Style Silent Check Valve Specifications and Applications for Various Industries

Wafer Type Silent Check Valve An Overview

The wafer type silent check valve is a crucial component in fluid control systems, widely utilized in various applications due to its numerous advantages. Unlike traditional check valves, which can produce significant noise and turbulence, the wafer type silent check valve is designed to operate quietly, ensuring smooth and efficient flow management in pipelines.

Design and Functionality

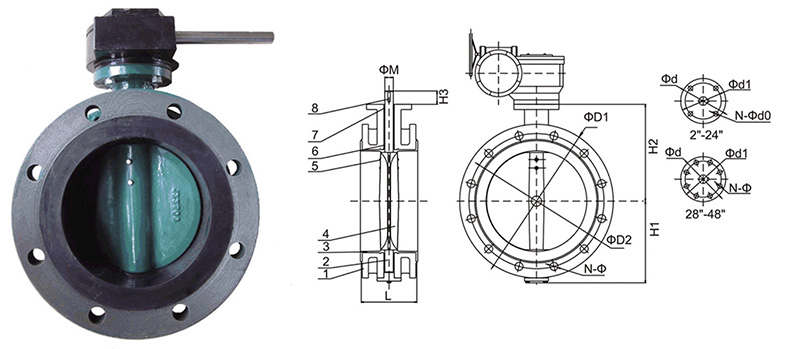

The wafer type silent check valve features a compact, lightweight design that makes it easy to install between flanges in a piping system

. This configuration is particularly beneficial in applications with limited space. The valve operates on a simple yet effective principle it allows fluid to flow in one direction while preventing backflow. This is achieved through a disc mechanism that opens with the forward flow and closes automatically when the flow reverses. The unique design minimizes the impact of the disc upon closure, significantly reducing noise and the risk of water hammer, a common issue with conventional check valves.Advantages

wafer type silent check valve

One of the most significant advantages of the wafer type silent check valve is its ability to maintain a steady flow rate and pressure, which is essential for the efficient operation of various systems, including HVAC, water supply, and industrial processes. The low profile of the valve contributes to lower installation costs, as it requires less material and labor compared to larger, bulky alternatives. Additionally, the use of high-quality materials in the construction of these valves enhances their durability and resistance to corrosion, making them ideal for use in harsh environments.

Applications

Wafer type silent check valves are commonly used in a wide range of industries, including water treatment, chemical processing, and power generation. In municipal water systems, they help prevent backflow, ensuring the safety and reliability of water supply. In industrial applications, these valves play a vital role in maintaining process integrity by preventing reverse flow in pipelines carrying fluids under pressure.

Conclusion

In conclusion, the wafer type silent check valve represents a critical advancement in fluid control technology. Its design not only enhances operational efficiency but also prioritizes noise reduction and durability. As industries continue to seek solutions for efficient fluid management, the wafer type silent check valve will remain an invaluable choice, combining functionality with a compact design to meet the demands of modern applications. With their myriad benefits, these valves prove to be a wise investment for any system requiring reliable flow control and protection against backflow.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025