nov . 11, 2024 15:29 Back to list

flange type silent check valve

Understanding Flange Type Silent Check Valves

Flange type silent check valves are integral components in various fluid systems, playing a vital role in maintaining the efficiency and safety of pipelines. As a passive device, a check valve specifically allows fluid to flow in one direction while preventing backflow, thus protecting pumps, compressors, and other equipment from damage caused by reverse flow.

What is a Flange Type Silent Check Valve?

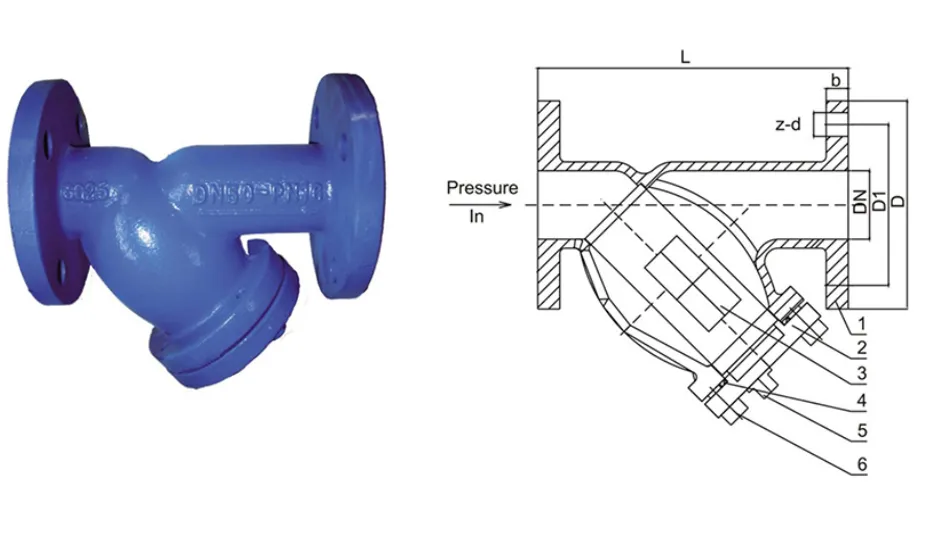

A flange type silent check valve is named for its design that includes flanged connections. This feature allows for easy installation and maintenance, as the valve can be bolted directly onto the pipeline. These valves operate automatically, responding to the fluid's movement without the need for manual intervention.

The term “silent” refers to the valve's design, which minimizes noise during operation. Unlike traditional check valves that can create a slamming noise when the fluid flow is interrupted, silent check valves employ a slow-closing mechanism. This reduces the sound and vibration associated with the sudden stop of fluid, making them ideal for applications in residential, commercial, and industrial settings where noise reduction is crucial.

Key Features and Benefits

1. Design and Construction Flange type silent check valves are typically made from durable materials such as cast iron, stainless steel, or PVC, depending on the application and the fluid being handled. The flanged design allows for a secure and leak-proof connection, accommodating a wide range of pipeline sizes.

2. Backflow Prevention The primary function of this valve is to prevent backflow, which can cause operational issues in fluid systems. By ensuring that fluid only moves in one intended direction, silent check valves safeguard pumps and other equipment from reverse flow-related damages.

3. Noise Reduction The silent operation of these valves is one of their standout features. In systems susceptible to water hammer—a phenomenon where a pressure surge occurs due to sudden changes in fluid velocity—silent check valves help to mitigate this problem, thereby extending the life of the system.

4. Efficiency These valves are designed to open and close fluidly in response to changes in flow, ensuring that the system maintains optimum efficiency. Their design minimizes pressure loss, which can be critical in maintaining system performance.

flange type silent check valve

5. Versatility Flange type silent check valves can be utilized in various applications, including water supply, sewage treatment, HVAC systems, and industrial liquid handling. Their adaptability to different media and conditions makes them valuable components in numerous sectors.

Applications

Flange type silent check valves are commonly found in

- Water Treatment Facilities They prevent backflow during filtration processes, ensuring clean and safe drinking water. - HVAC Systems By controlling the direction of flow in chilled water systems and preventing reverse flow, these valves enhance energy efficiency. - Industrial Processes In manufacturing and processing industries, consistent fluid transportation is vital. Silent check valves help maintain the flow direction, protecting equipment from possible damage.

Installation and Maintenance

Proper installation of flange type silent check valves is imperative to ensure optimal performance. The flanges should be aligned correctly, and gasket seals should be employed to prevent leaks. It’s essential to follow the manufacturer’s specifications regarding torque settings and installation configurations.

Regular maintenance is also necessary to ensure the long-term functionality of silent check valves. Periodic inspections for wear and tear, along with cleaning, can help prevent potential issues before they escalate.

Conclusion

Flange type silent check valves offer a seamless and efficient solution for fluid flow management across various applications. Their durable construction, minimal noise production, and essential backflow prevention capabilities make them vital to maintaining the integrity and efficiency of fluid systems. With a proper understanding of their design, advantages, and maintenance, industries can significantly enhance their operational reliability and extend the lifespan of their pipelines and equipment.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025