නොවැ. . 05, 2024 21:20 Back to list

swing type check valve

Understanding Swing Type Check Valves A Comprehensive Overview

Swing type check valves play a crucial role in various fluid systems by preventing backflow, thereby ensuring the efficient and safe operation of piping systems. In this article, we will delve into the functionality, design, applications, advantages, and maintenance of swing type check valves.

What is a Swing Type Check Valve?

A swing type check valve is a mechanical device designed to allow fluid to flow in one direction while preventing its backflow. Unlike other check valves, which may have a spring-loaded mechanism, the swing type relies on a hinged disk or flap that opens with forward flow and closes against the seat of the valve when flow reverses. This simple yet effective mechanism is essential in preventing potential damage caused by backflow, which can lead to contamination or system failures.

Design and Functionality

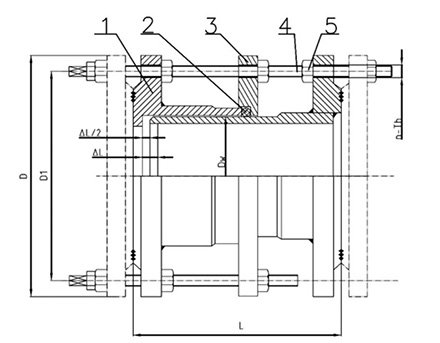

The design of a swing type check valve typically includes the following components

1. Body The main structure that houses the internal components and connects to the pipeline. 2. Hinged Disc A flap that swings open to allow flow and closes off the flow when back pressure occurs. 3. Seat The surface against which the hinged disc seals to prevent backflow. 4. Bushing or Armature Components that support the hinged disc and allow it to pivot smoothly.

When fluid moves through the valve in the intended direction, the pressure builds up underneath the disc, causing it to swing open. In contrast, if the flow reverses, the disc naturally swings back down due to gravity (or the weight of the disc) and seals against the seat, effectively halting any reverse flow.

Applications of Swing Type Check Valves

Swing type check valves are widely utilized in various industries and applications, including

- Water and Wastewater Treatment To prevent backflow and contamination in treatment plants. - HVAC Systems In heating and cooling systems to control flow direction and prevent leaks. - Chemical Processing To ensure the safety of hazardous fluids and maintain operational integrity. - Power Generation In steam and water systems to prevent backflow that can damage equipment.

swing type check valve

Their versatility and reliability make them suitable for countless applications across different sectors.

Advantages of Swing Type Check Valves

1. Simplicity of Design The straightforward design leads to ease of installation and maintenance, reducing operational costs. 2. Low Pressure Loss Swing type check valves typically offer lower pressure drops compared to other types, which is beneficial for system efficiency. 3. Durability Constructed from robust materials, these valves can withstand high pressures and temperatures, contributing to a longer service life. 4. Self-Operating These valves operate automatically, requiring no external power source or control system, enhancing reliability.

Considerations for Use

While swing type check valves offer numerous benefits, there are also considerations to keep in mind

- Installation Position These valves should be installed horizontally or vertically, as improper orientation can affect their functionality. - Flow Conditions High-velocity flows may cause the disc to chatter, leading to wear over time. It is essential to assess the conditions under which the valve will operate. - Pressure Ratings Always ensure that the swing check valve’s pressure rating aligns with the requirements of your system to avoid failure.

Maintenance and Inspection

Maintaining swing type check valves is vital for ensuring their longevity and reliability. Regular inspection for signs of wear, corrosion, or debris buildup is essential. Cleaning the valve and ensuring it opens and closes smoothly will help prevent potential issues. It is also advisable to check the seating surface for signs of damage, which could compromise the valve’s ability to prevent backflow effectively.

Conclusion

Swing type check valves are integral components in fluid management systems, providing a reliable solution for preventing backflow. Their design simplicity, durability, and efficient operation make them an ideal choice for a wide range of applications. However, proper installation, consideration of flow conditions, and routine maintenance are necessary to ensure optimal performance and longevity. Understanding these aspects enables engineers and facility managers to make informed decisions when integrating swing type check valves into their systems, ultimately contributing to enhanced safety and efficiency in fluid handling operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025