නොවැ. . 19, 2024 19:10 Back to list

rubber check valve

Understanding the Rubber Check Valve A Comprehensive Guide

Rubber check valves are essential components in various fluid control systems, serving primarily to prevent backflow and ensure the unidirectional flow of liquids and gases. They are widely used in industries ranging from municipal drinking water systems to wastewater treatment and industrial applications. This article delves into the functionality, applications, and advantages of rubber check valves.

What is a Rubber Check Valve?

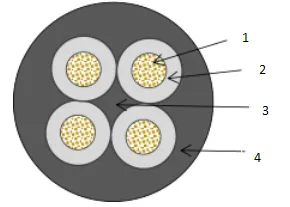

A rubber check valve is a type of one-way valve that allows fluid to flow in a single direction while preventing backflow. Its primary component is made from durable rubber or elastomeric materials, which provide excellent sealing and flexibility. The basic design consists of a body, a disc or flap, and a spring or weight mechanism that aids in the closing action.

How Does it Work?

The operation of a rubber check valve is straightforward. When fluid flows in the desired direction, the pressure forces the disc or flap to open, allowing the fluid to pass through. Once the flow decreases or reverses, the pressure drop causes the disc to close, effectively sealing the valve and preventing any backflow. This simple yet efficient mechanism makes rubber check valves highly effective in controlling fluid dynamics in various systems.

Applications of Rubber Check Valves

2. Wastewater Treatment These valves are commonly found in wastewater treatment facilities, where they help maintain the flow of treated water and prevent sewage from re-entering treatment processes.

rubber check valve

3. Pumping Systems In pump systems, rubber check valves protect the pump from backpressure that could damage its components. They ensure that once fluid is pumped out, it cannot flow back into the pump.

4. Industrial Applications Many industries utilize rubber check valves in their piping systems for chemical processing, food and beverage production, and HVAC systems, where control of flow direction is vital.

Advantages of Rubber Check Valves

1. Durability Rubber materials are resistant to wear and tear, which contributes to the longevity of these valves. They can handle various fluids, including corrosive substances when made from the right rubber compounds.

2. Cost-Effectiveness Compared to metal check valves, rubber check valves are often more cost-effective both in terms of initial purchase and maintenance. Their lightweight nature also makes them easier to install.

3. Flexibility The elasticity of rubber allows for a tight seal even under varying pressure conditions, enhancing their efficiency in preventing leaks.

4. Low Noise Operation Rubber check valves operate quietly compared to their metal counterparts, making them suitable for applications where noise reduction is essential.

Conclusion

Rubber check valves are vital components in fluid control systems, ensuring safe and efficient operations across various sectors. Their simple design, combined with robust functionality, makes them an excellent choice for preventing backflow and maintaining the integrity of fluid systems. As industries continue to evolve and seek efficient solutions, the relevance of rubber check valves will remain significant, providing reliable performance and contributing to sustainable practices in fluid management.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025