Dec . 02, 2024 02:02 Back to list

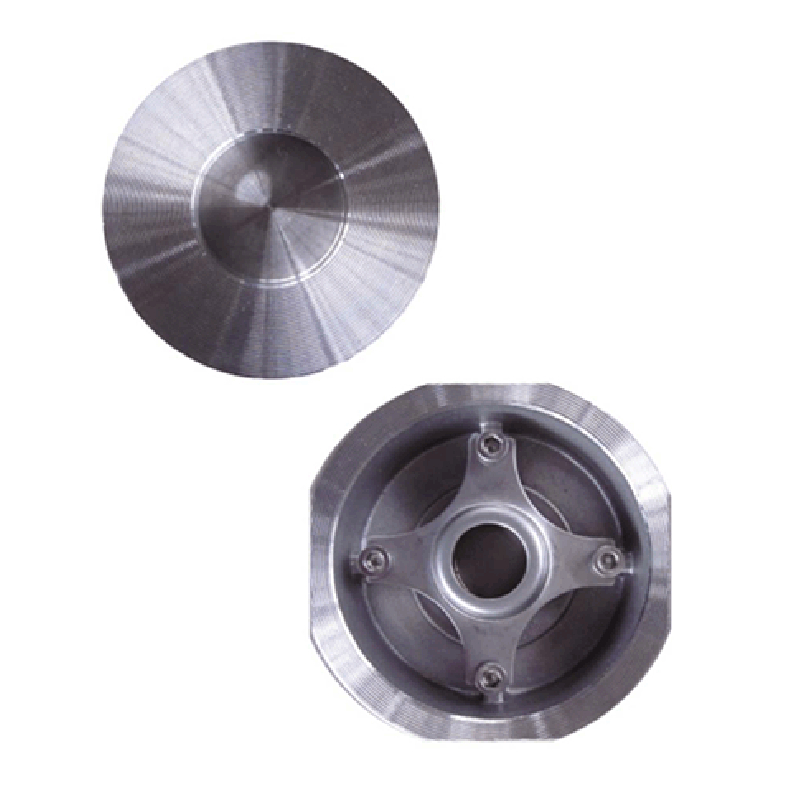

stainless steel globe valve

Understanding Stainless Steel Globe Valves

In various industrial applications, the need for effective flow control within pipelines is crucial. A key player in achieving this is the stainless steel globe valve. Renowned for their reliability, durability, and efficient performance, stainless steel globe valves are indispensable components in many industries, including oil and gas, water treatment, food processing, and chemical manufacturing.

What is a Globe Valve?

A globe valve is a type of valve that uses a spherical body to regulate fluid flow. It consists of a movable disk (or plug) and a stationary ring seat. The design allows for precise control over the flow of fluids, providing a tight seal when closed. This valve type is characterized by its distinctive shape, which generally consists of two halves separated by a baffle. This creates a smooth flow path, minimizing turbulence and pressure loss.

Advantages of Stainless Steel

Stainless steel is a popular material choice for globes valves due to its favorable properties. It has excellent corrosion resistance, which is vital when dealing with various liquids and gases, some of which may be highly corrosive. Stainless steel valves can withstand extreme temperatures and pressures, making them suitable for a wide range of applications. Additionally, stainless steel is relatively low maintenance compared to other materials, which can save businesses time and money in the long run.

Applications of Stainless Steel Globe Valves

Stainless steel globe valves find applications across multiple sectors

stainless steel globe valve

1. Oil and Gas In the oil and natural gas extraction and processing industry, these valves are often used to control the flow of crude oil and gas. They are essential in keeping systems safe and efficient, particularly in high-pressure environments.

2. Water Treatment In water treatment facilities, globe valves play a crucial role in managing the flow of water through filtration and treatment processes. Their ability to maintain a tight seal prevents leakage, ensuring the purity of treated water.

3. Food Processing The food and beverage industry demands high hygiene standards. Stainless steel is non-reactive and easy to clean, making stainless steel globe valves the go-to choice for regulating the flow of liquids in this sector.

4. Chemical Manufacturing Chemical plants often handle hazardous materials, and stainless steel's corrosion resistance is vital. Globe valves are used to manage the flow of chemicals safely and effectively.

Installation and Maintenance

For optimal performance, proper installation of stainless steel globe valves is crucial. They should be installed in a way that allows easy access for maintenance and inspection. Regular maintenance checks can prevent issues and extend the valve's lifespan. Common maintenance practices include checking for leaks, ensuring proper sealing, and inspecting for any signs of wear and tear.

Conclusion

In summary, stainless steel globe valves are essential components for controlling fluid flow in various industries. Their durability, corrosion resistance, and efficiency make them the preferred choice in applications where safety and reliability are critical. As industries continue to evolve with new technologies and demands, the relevance of these valves will only increase. Businesses must invest in high-quality stainless steel globe valves to ensure their operations run smoothly and effectively, safeguarding both equipment and processes. Whether in energy production, water management, or food processing, these valves are testament to the critical role of quality engineering in industrial success.

Share

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025