Dec . 06, 2024 21:10 Back to list

severe service

Understanding Severe Service Ensuring Reliability in Extreme Conditions

Severe service refers to the demanding environments and conditions in which industrial equipment operates, particularly in the context of valves, pumps, and other critical components in various industries. In sectors such as oil and gas, chemical processing, power generation, and water treatment, equipment often faces extreme temperatures, corrosive substances, high pressures, and abrasive materials. This necessitates a comprehensive understanding of severe service and how to properly equip systems to withstand these unique challenges.

Characteristics of Severe Service Conditions

Severe service can be distinguished by several defining characteristics. Firstly, high temperatures can lead to thermal expansion, potential material degradation, and changes in properties that may compromise performance. Similarly, extremely low temperatures can cause brittleness in certain materials, making them prone to fracture under mechanical stress.

Secondly, corrosive media such as acids, bases, and saltwater can significantly limit the lifespan of conventional equipment. Standard materials may rust, corrode, or otherwise degrade when subjected to such harsh environments. Hence, the use of specialized coatings, alloys, or polymer linings is often necessary to enhance resistance to corrosive agents.

Moreover, high pressures are commonplace in industries like oil and gas extraction, where deep offshore drilling can result in pressures exceeding thousands of psi. Equipment must not only survive these pressures but also function reliably under them.

Lastly, the presence of solid particulates presents additional challenges. In industries such as mining and wastewater treatment, abrasive materials can wear down equipment surfaces, leading to premature failure and costly downtime. Solutions may involve harder materials or innovative design approaches that minimize erosion and improve equipment resilience.

Design and Material Selection for Severe Service

severe service

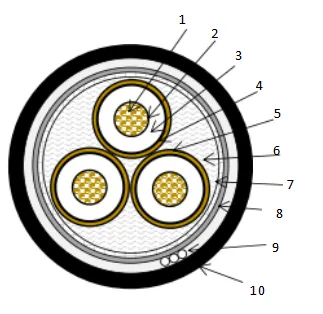

Given the complexities of severe service environments, careful consideration must be given to the design and material selection of components

. For instance, valves used in severe service applications often require robust body materials like stainless steel, duplex stainless steel, or even more exotic alloys such as Inconel or Hastelloy. These materials not only resist corrosion but also provide the necessary strength to withstand high pressures.Additionally, the design must take into account factors such as flow characteristics, temperature fluctuations, and thermal expansion. Engineers may opt for features like blow-out proof stems, reinforced seat designs, and special sealing materials that can endure extreme conditions without losing integrity.

Monitoring and control systems also play a crucial role in severe service applications. Regular inspection and maintenance can help detect early signs of wear or failure, allowing for timely interventions. Advanced technologies such as predictive maintenance and real-time monitoring can enhance reliability, ensuring that equipment operates within safe parameters.

Industry Applications and Case Studies

Numerous industries depend on equipment that can withstand severe service conditions. In oil and gas, for example, valves are often used in hostile environments, such as offshore platforms, where they must endure saltwater corrosion and high-pressure gas flows. Case studies have shown that the implementation of specialized valves, designed explicitly for severe service, has significantly reduced failure rates and enhanced operational efficiency.

Similarly, in the chemical processing industry, reactors and pipelines must handle various hazardous materials under extreme conditions. The transition to using high-performance polymer linings and advanced mechanical seals has greatly improved safety and longevity in such applications.

Conclusion The Road Ahead for Severe Service Solutions

As industries continue to push the boundaries of exploration and production in increasingly challenging environments, the need for reliable severe service solutions will only grow. Innovative materials, advanced engineering techniques, and smart monitoring technologies will be critical in ensuring the integrity and efficiency of equipment operating in these demanding conditions. By understanding the unique challenges associated with severe service, industries can better equip themselves to handle the rigors of modern demands, ultimately leading to improved safety, reliability, and operational success.

Share