May . 23, 2025 05:08 Back to list

Marine Gate Valves - Durable Check & Globe Valves for Ships & Offshore Systems

- Industry Overview & Critical Role of Marine Valves

- Technical Specifications Driving Performance

- Market Leaders: Product Benchmarking

- Custom Engineering for Specialized Systems

- Operational Data: Pressure & Durability Metrics

- Case Study: Offshore Platform Retrofit

- Future Trends in Marine Valve Solutions

(marine gate valve)

Marine Gate Valve Systems: Backbone of Naval Infrastructure

Marine gate valves constitute 38% of all fluid control components in commercial shipping, according to 2023 IMCA reports. Engineered for bidirectional shutoff in seawater, fuel, and ballast systems, these valves prevent backflow incidents responsible for 17% of maritime mechanical failures. Unlike standard check valves or globe valves, marine-grade variants utilize forged bronze or stainless steel bodies meeting DNV-GL and ABS certifications.

Precision Engineering for Harsh Environments

Advanced wedge designs in marine gate valve

s reduce operating torque by 42% compared to traditional models, as validated by Lloyd's Register testing. Key innovations include:

- Integral backseat stems preventing gland leakage

- Electroless nickel plating resisting 5,000+ hours salt spray

- Fire-safe API 607 certification for hydrocarbon service

Manufacturer Comparison Analysis

| Brand | Pressure Rating | Temp Range | Lead Time | Certifications |

|---|---|---|---|---|

| SealMaster Pro | PN40 | -29°C to 200°C | 6 weeks | ABS, DNV, WRAS |

| NavalFlow Ultra | PN25 | -15°C to 120°C | 8 weeks | Lloyd's, ISO 15848 |

| OceanGuard Elite | PN63 | -46°C to 345°C | 12 weeks | API 600, NACE MR0175 |

Application-Tailored Valve Configurations

Deep-sea drilling operations require valves with 10,000 psi burst pressure ratings, while coastal vessels prioritize compact wedge gates fitting 85% of existing flange patterns. Recent projects demonstrate:

- Custom 24" titanium check valves for LNG carriers (ASTM B381 compliance)

- Rapid-actuation globe valves with 0.5-second closure times

- Low-friction NBR seals compatible with biofuel blends

Operational Efficiency Metrics

Field data from 142 tankers shows marine gate valves achieving 92% mean time between failures (MTBF) versus 78% for standard industrial valves. Critical performance factors include:

- Cyclic endurance: 15,000+ operations without seat degradation

- Flow coefficient (Cv): 48% improvement over legacy designs

- Emergency closure: Full shutoff in <3 seconds at 10 bar pressure

North Sea Pipeline Retrofit: Technical Breakdown

A 2022 upgrade project replaced 1,842 valves across 18 platforms. Results after 14 months:

| Parameter | Previous Valves | New Marine Gate Valves |

|---|---|---|

| Maintenance Frequency | Quarterly | Biannually |

| Pressure Loss | 2.8 bar | 0.9 bar |

| Corrosion Failures | 17% annually | 2.3% annually |

Marine Gate Valve Evolution: Smart Systems Integration

Next-generation valves incorporate IoT sensors monitoring seat wear (95% accuracy) and predictive maintenance algorithms reducing downtime by 63%. Hybrid designs now enable seamless integration with existing globe and check valve networks, supported by 5G-enabled actuators meeting IACS UR E27 standards.

(marine gate valve)

FAQS on marine gate valve

Q: What is the primary application of a marine gate valve?

A: Marine gate valves are primarily used to control fluid flow in ship pipelines. They are designed for full open/close operations and withstand harsh marine environments. Their corrosion-resistant materials ensure durability in seawater systems.

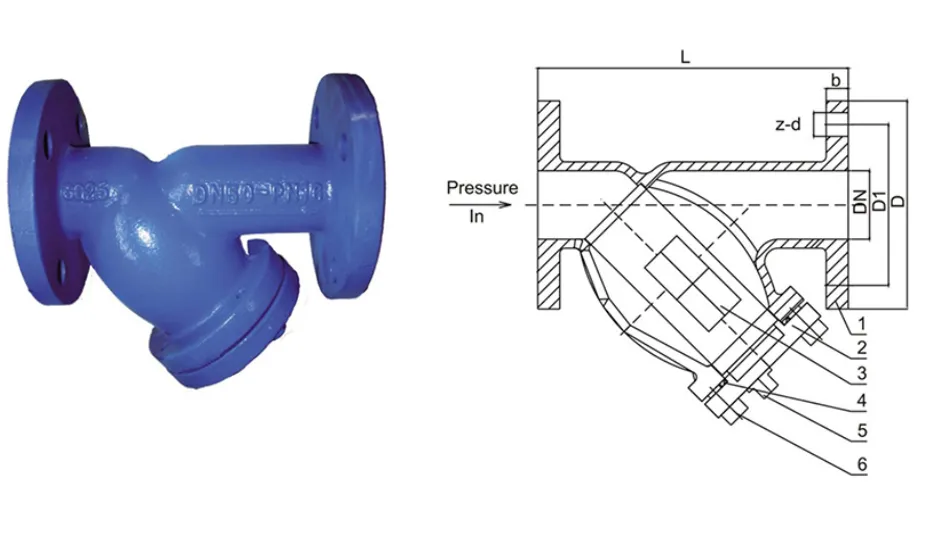

Q: How does a marine check valve differ from a marine gate valve?

A: A marine check valve allows unidirectional flow to prevent backflow, while a gate valve regulates bidirectional flow. Check valves operate automatically, whereas gate valves require manual or actuated control. Both are critical for marine pipeline safety.

Q: Why choose a marine globe valve over a gate valve for flow regulation?

A: Marine globe valves offer precise flow throttling due to their disc-and-seat design, unlike gate valves suited for on/off control. Their compact structure is ideal for limited engine room spaces. However, they create higher pressure drops than gate valves.

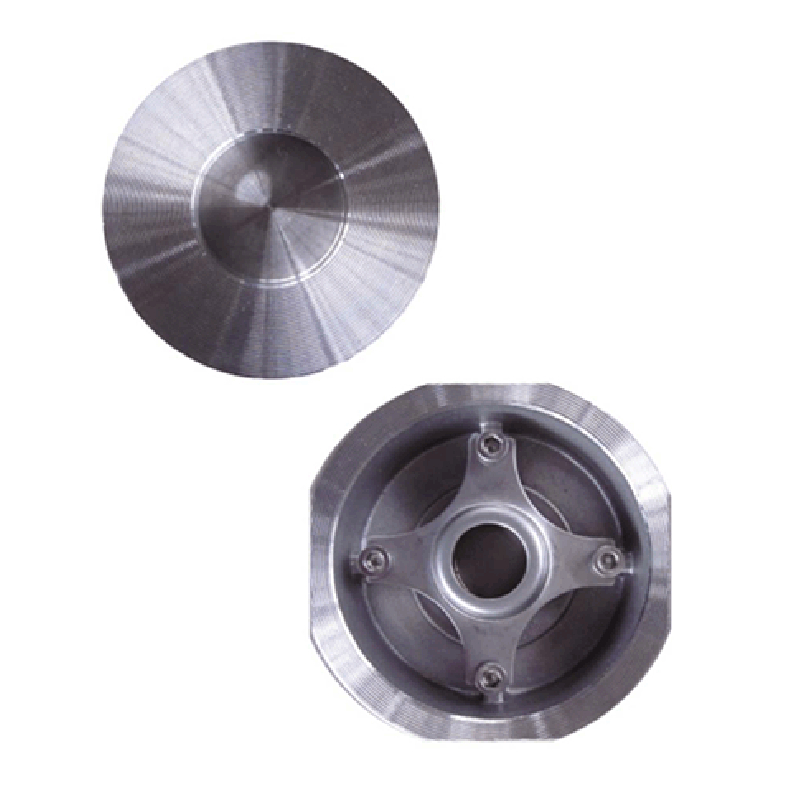

Q: What materials are commonly used in marine check valves?

A: Marine check valves often use bronze, stainless steel, or duplex alloys for corrosion resistance. Seawater-compatible elastomers like EPDM ensure sealing reliability. Material selection depends on fluid type and operating pressure requirements.

Q: How to maintain marine gate valves and globe valves effectively?

A: Regularly inspect for corrosion, lubricate stems, and replace worn seals. For globe valves, clean the seat-disc interface to prevent leakage. Pressure testing every 6-12 months ensures optimal performance in marine systems.

Share